Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Ever wonder how to achieve microscopic-level material modification with exceptional accuracy? OPMT Laser’s advanced femtosecond laser technology delivers precision beyond imagination. Our systems, including the state-of-the-art Micro3D L530V five-axis femtosecond laser machining center, utilize light pulses measured in femtoseconds – an astonishing one quadrillionth of a second! These ultra-short bursts of energy are revolutionizing high-precision manufacturing and surface treatment.

OPMT Laser stands at the cutting edge of this innovation. Our Micro3D L530V, a five-axis femtosecond laser machining center, enables you to achieve unparalleled precision in your complex projects, such as microfabrication, surface texturing, and the processing of hard and brittle materials like PCD, ceramics, and mold steel.

To truly appreciate the power of OPMT’s femtosecond lasers, understanding the incredibly brief duration of a femtosecond is key. A femtosecond is one quadrillionth of a second (10^-15 seconds). In this fleeting moment, light travels a mere 0.3 micrometers, a distance comparable to the size of a virus. This extraordinarily short pulse duration allows our femtosecond lasers to deliver energy with extreme precision, significantly minimizing heat diffusion and unwanted thermal effects on surrounding areas. This characteristic, enabling virtually “cold processing“, is critical in applications demanding the highest accuracy, including micromachining, surface microstructuring (LIPSS), and the precision machining of components where even minimal thermal damage can compromise the final result, such as in mold making and potentially medical devices requiring intricate and biocompatible surfaces. Discover the possibilities with OPMT Laser’s femtosecond laser solutions.

Femtosecond lasers operate based on the principle of photodisruption, enabling high-precision material modification with minimal thermal influence. When a femtosecond laser pulse, as employed in OPMT Laser’s Micro3D L530V five-axis femtosecond laser machining center, is focused onto a material, the concentrated energy induces rapid ionization, leading to the formation of microplasma. This microplasma undergoes rapid expansion, generating a shockwave that precisely ablates or separates the material at the focal volume. OPMT Laser’s femtosecond laser technology leverages this mechanism for demanding high-precision applications.

The photodisruption process encompasses the following key stages:

A significant benefit of femtosecond lasers, particularly relevant to the high-precision machining capabilities offered by OPMT Laser, is the minimal thermal load imparted during material processing. Conventional lasers often induce substantial thermal damage, leading to melting, cracking, and alterations in material properties. Due to the ultrafast ablation achieved by femtosecond lasers, insufficient time is available for significant heat transfer, thereby preserving the integrity of the adjacent material. This is especially advantageous when processing sensitive materials such as PCD, ceramics, and hard alloys, which are within the processing capabilities of OPMT Laser’s equipment. The precise processing with a minimized heat-affected zone is critical for achieving high accuracy and smooth transitions in cutting edges, as demonstrated in magnified images of PCD tools machined using OPMT Laser technology. OPMT Laser’s emphasis on processing ultra-hard materials greatly benefits from this inherent characteristic of femtosecond lasers.

The performance and applicability of femtosecond lasers, such as those integrated into OPMT Laser’s Micro3D L530V five-axis femtosecond laser machining center, are determined by several key parameters:

Understanding and carefully controlling these critical parameters are fundamental to achieving the desired outcomes in various applications of femtosecond laser technology offered by OPMT Laser, including microfabrication, surface texturing, and the processing of ultra-hard materials.

Femto lasers’ unique characteristics—precision, minimal thermal impact, and the capacity to ablate nearly any material—have rendered them crucial across diverse sectors . These lasers deliver short bursts of light, measured in femtoseconds (one quadrillionth of a second), enabling unparalleled precision when interacting with various materials.

The primary medical application of femto lasers lies in ophthalmology, where they have revolutionized procedures like LASIK and cataract surgeries . Femto lasers promote safer procedures and quicker recovery times because they can process tissue in a 3-D volume without affecting its surface.

Femto lasers are essential in material processing for their precision and minimal thermal damage when ablating materials .

Femto lasers are critical for studying ultrafast phenomena in physics, chemistry, and biology .

Femto lasers play a role in telecommunications, especially in dense wavelength division multiplexing (DWDM) systems, which increases optical fiber bandwidth by transmitting multiple data channels at different wavelengths . Femto lasers generate the short pulses needed for high-speed data transmission in DWDM systems.

Femtosecond lasers offer considerable advantages over traditional methods, but a thorough understanding of their limitations is essential for optimal use across various applications.

OPMT (Original Point Intelligent Technology) has integrated advanced femtosecond laser technology across its precision manufacturing portfolio, including the flagship Micro3D L530V and L570V five-axis machining centers. Based on documented performance metrics and industry case studies, these systems deliver transformative advantages for modern manufacturing challenges:

Unmatched Sub-Micron Precision for Complex Material Processing: OPMT’s femtosecond laser systems consistently achieve positioning accuracy of ±0.003mm with repeatability of ±0.002mm, as verified in the Micro3D L530V specifications. This exceptional precision results from ultra-short 20W femtosecond laser pulses that interact with materials before thermal effects can propagate. OPMT’s proprietary iMTOS CNC control system enhances this precision through sophisticated 3D path planning and real-time adaptive control. This technology enables manufacturers to process complex contours in traditionally challenging materials like PCD, CBN, ceramics, and high-temperature alloys with surface finishes measuring less than 0.1μm roughness. Precision tool manufacturers using OPMT systems report up to 20× efficiency improvements over traditional methods while maintaining consistent dimensional accuracy across production runs.

Material Integrity Preservation Through Cold Processing Technology: OPMT’s femtosecond laser technology fundamentally transforms material removal through photochemical rather than photothermal mechanisms. This “cold processing” creates virtually no thermal stress or micro-cracking – a critical advantage when processing brittle or sensitive materials. Comparative testing with OPMT’s LightGRIND series demonstrates that femtosecond-processed surfaces maintain their original crystalline structure with no detectable hardness variations, even at microscopic examination levels. For manufacturing applications like woodworking tool production, this translates directly to longer tool life and superior cutting performance, with documented examples showing PCD tools processed on OPMT systems achieving both exceptional surface quality and significantly extended service life. Cost analysis data further indicates operating cost reductions of up to 53% compared to conventional EDM processing for certain applications.

Near-Zero Heat-Affected Zone for Next-Generation Manufacturing Requirements: The virtual elimination of Heat-Affected Zone (HAZ) represents OPMT’s most significant technological advantage. While conventional laser processing creates HAZ regions extending hundreds of microns into materials, OPMT’s femtosecond systems consistently demonstrate HAZ measurements below detection thresholds. This capability enables entirely new manufacturing applications, particularly in mold texturing, medical components, and microelectronics. The Micro3D L570V mold texturing system specifically leverages this advantage to create micro-dimensional patterns with unprecedented precision and repeatability. The technology enables complex 3D texturing with up to 30-50 distinct layers compared to the 3-5 layer limitation of traditional chemical texturing, eliminating side etching and edge effects while processing curved, inclined, and spherical surfaces that conventional methods cannot achieve. This advancement satisfies the growing industry demand for environmentally friendly, high-precision surface texturing without chemical pollutants.

Investment Optimization for Manufacturing Applications: While femtosecond laser systems traditionally require significant capital investment, OPMT Laser has engineered cost-effective precision manufacturing solutions through its Micro3D L530V/L570V platforms. These systems achieve positioning accuracy of ±0.003mm with repeatability of ±0.002mm while integrating multiple manufacturing capabilities into a single platform. Cost analysis data from OPMT’s woodworking tool manufacturing case studies demonstrates operating cost reductions of up to 53% compared to conventional EDM processing, creating compelling ROI despite higher initial costs. This efficiency stems from femtosecond processing eliminating secondary operations typically required with traditional manufacturing methods.

Streamlined Operation Through Intelligent Control Systems: OPMT addresses the technical complexity traditionally associated with femtosecond laser operations through its proprietary iMTOS CNC control system. This intelligent platform combines sophisticated 3D path planning with an intuitive interface specifically designed for production environments. The integrated high-definition CCD camera system and high-precision probe enable automated workpiece alignment and in-process measurement, significantly reducing specialized operator knowledge requirements. This systematic approach to operational simplification makes advanced femtosecond technology accessible to conventional manufacturing teams while maintaining micron-level processing capabilities for demanding applications.

Enhanced Reliability Through Advanced System Architecture: OPMT’s femtosecond laser machining centers feature a modular design that fundamentally transforms maintenance requirements in industrial settings. The systems incorporate comprehensive dust filtration and environmental control systems that protect sensitive optical components while ensuring consistent processing results. The Micro3D platforms utilize advanced beam path engineering with automated calibration capabilities to maintain precision while minimizing service interventions. Combined with OPMT’s preventative maintenance protocols and rapid-response service infrastructure, these design innovations enable documented system availability exceeding 95% in continuous manufacturing applications, addressing a critical consideration for production environments.

Femto lasers are a specialized category within laser technology, and understanding their utility requires comparing them against other prevalent types, including nanosecond lasers, picosecond lasers, and excimer lasers . Each laser type is distinguished by unique properties and applications. Selecting the most appropriate laser hinges on the application’s specific needs, balancing factors like precision, cost, and material compatibility.

| Feature | Femto Lasers | Nanosecond/Picosecond Lasers | Excimer Lasers |

|---|---|---|---|

| Pulse Duration | Extremely short pulses in the femtosecond range (10^-15 seconds); this ultrafast pulse duration enables highly precise material processing with minimal heat generation. Applications include micromachining, biomedical imaging, and scientific research . | Shorter pulses than continuous-wave lasers; nanosecond pulses are in the range of 10^-9 seconds, while picosecond lasers emit pulses in the 10^-12 second range . Picosecond lasers are utilized in tattoo removal and medical aesthetics . | Emit pulses in the nanosecond range but use a reactive gas, like noble gases and halides; variable pulse duration dependent on specific laser design and gas mixture . Mainly for vision correction like LASIK . |

| Precision | Offer the highest level of precision due to their extremely short pulse duration, enabling material ablation or modification with minimal thermal damage; suitable for microscale and nanoscale applications . Femto lasers are used in creating microfluidic devices and advanced glass cleaving . | Provide high precision, making them suitable for various material processing applications; precision is lower than femtosecond lasers but sufficient for many industrial uses . Used in laser marking and solar cell scribing . | Offer high precision and are particularly effective in procedures like LASIK for corneal reshaping . Precision is achieved through controlled tissue ablation, though thermal effects are more pronounced than with femtosecond lasers . |

| Heat Affected Zone (HAZ) | Create a minimal heat-affected zone due to the ultra-short pulse duration . Material is vaporized almost instantly, preventing heat from spreading to the surrounding area, making it advantageous where precision is critical . | Produce a more significant heat-affected zone compared to femtosecond lasers . The longer pulse duration allows more time for heat to conduct into the material, potentially causing thermal damage . | Generate a moderate heat-affected zone . The extent of thermal damage is more than femtosecond lasers but less than that of nanosecond or continuous-wave lasers . |

| Common Uses | Extensively used in eye surgery (LASIK, cataract surgery), micromachining, scientific research (ultrafast optics, spectroscopy), and biomedical imaging (two-photon microscopy) . Also useful in microelectronics and semiconductor device fabrication . | Commonly employed in material processing applications such as laser marking, engraving, and cutting . Used for a broad range of materials, including metals, plastics, and ceramics . | Predominantly utilized in vision correction procedures like LASIK and PRK, where they reshape the cornea by removing tissue . Effective in treating myopia, hyperopia, and astigmatism . Also used in dermatology for conditions like psoriasis and vitiligo. |

| Key Advantage | The ultra-precise and minimally invasive nature makes them ideal for applications requiring high accuracy and minimal thermal damage . Femto lasers facilitate “cold” processing, preventing heat transfer to the worked material . | Offer a cost-effective solution for material processing, balancing precision and speed for industrial applications. Nanosecond fiber lasers are used for cleaning applications. | Excel in corneal reshaping, providing effective vision correction with a well-established track record . The Zeiss MEL 90 excimer laser received FDA approval for myopia, hyperopia, and mixed astigmatism treatments . |

The domain of femtosecond laser technology is in perpetual evolution, characterized by relentless innovation that broadens its capabilities and applications across diverse industrial sectors. These swift developments are revolutionizing manufacturing processes and scientific research, delivering unprecedented precision and efficiency in material processing.

The continuous advancement of femtosecond lasers is centered on crucial aspects that amplify their practicality and accessibility in industrial applications.

Enhanced Efficiency and Miniaturization: Current engineering efforts focus on developing more compact, energy-efficient, and cost-effective femtosecond laser systems. OPMT Laser’s multi-axis CNC systems, particularly the LP550V Five-axis Ultrafast Laser Rotary Cutting Machine, exemplify this progress with their modularized beam path design and high-precision galvanometer achieving repeat positioning accuracy of 2 μrad. These advancements reduce footprint requirements and operational expenses, making this advanced technology accessible to a broader spectrum of manufacturing enterprises.

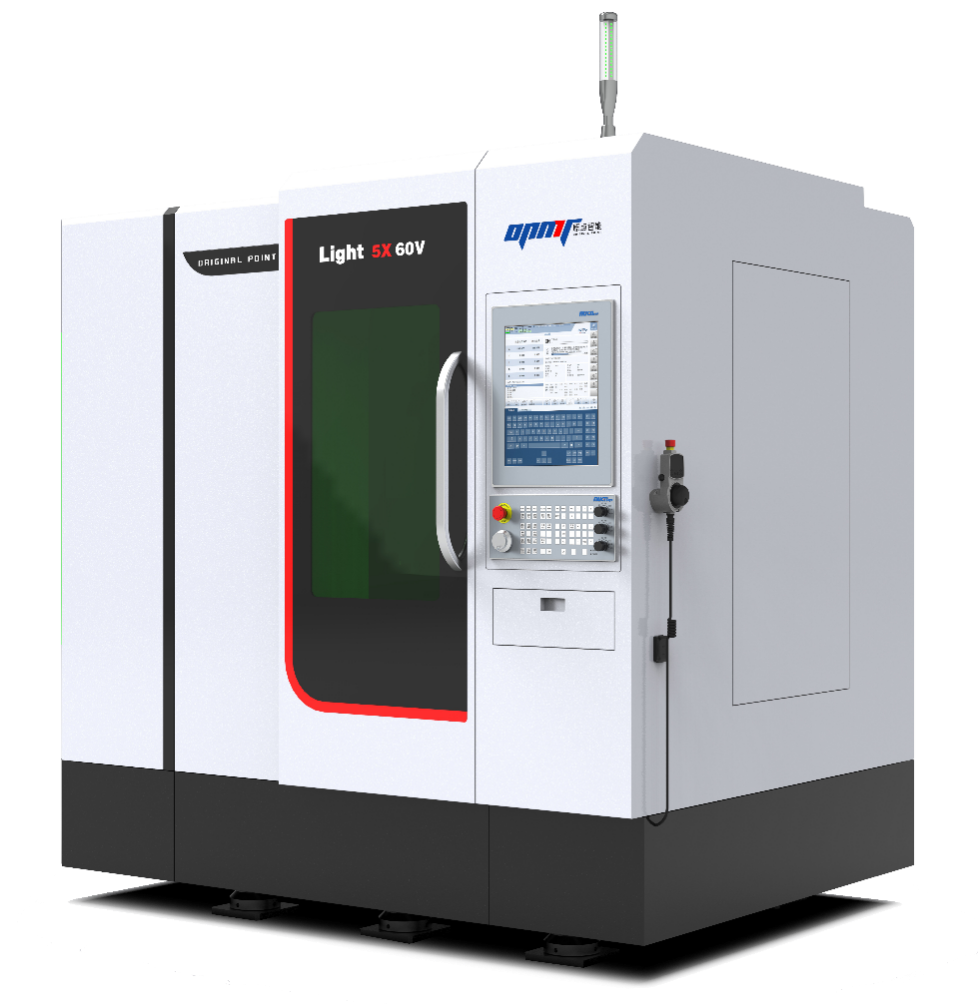

Advanced Materials Processing Capabilities: OPMT’s femtosecond laser systems excel in processing challenging materials including PCD, CBN, ceramics, and high-temperature alloys with minimal heat-affected zones. The Light 5X series vertical machining centers utilize natural marble beds with stable structure, achieving positioning accuracies of 0.005mm and repeat positioning accuracies of 0.003mm. This precision enables complex contour machining impossible with conventional methods.

Integration with AI and Machine Learning: OPMT Laser’s self-developed CNC systems incorporate advanced algorithms for path optimization and automated processing. The company’s mold texturing solutions feature intelligent generation of splicing linkage processing and automatic programming capabilities that transform 3D models directly into optimized machining paths. This AI-driven approach significantly reduces programming time while enhancing processing quality.

Advancements in Laser-Material Interaction: The company’s technology enables precise modification of material properties through controlled femtosecond pulse delivery, creating microstructures with feature sizes as small as 0.2mm. The Micro3D L570V Mold Texturing Laser Machine can process up to 30-50 texture layers compared to traditional methods that manage only 3-5 layers.

OPMT Laser’s femtosecond technology extends its influence into an array of specialized industrial applications.

Precision Medical Device Manufacturing: The LightMUT 750V Laser Grinding and Milling Compound Machining Center employs patented multi-laser nano-pico-femtosecond compound machining technology, enabling the production of implantable medical devices with complex geometries and stringent tolerance requirements. The system’s three-laser dual-beam-path time-sharing switching capability allows sequential compound machining in a single operation.

Automotive Component Processing: OPMT’s femtosecond laser systems are revolutionizing automotive manufacturing by enabling precise processing of components with complex geometries. The ability to process high-temperature alloys, ceramics, and composite materials without thermal damage makes these systems ideal for producing high-performance automotive parts. Examples include drilling cooling holes in turbine blades with diameters as small as 0.3mm in 2mm thick high-temperature alloy.

Advanced Electronics Manufacturing: In the 3C (Computer, Communication, Consumer Electronics) industry, OPMT’s femtosecond laser systems enable the micromachining of silicon carbide and other semiconductor materials with unprecedented precision. The LP550V can create holes with diameters ranging from 0.1-1mm with precision of 2μm, achieving remarkable pit-depth to pit-diameter ratios of up to 30:1.

Luxury Goods Surface Texturing: The Micro3D L570V system has transformed the luxury goods industry through its ability to create intricate surface textures with up to 50 layers of depth. This technology replaces traditional chemical texturing processes, offering environmentally friendly manufacturing with superior precision and reproducibility.

The full potential of femtosecond laser technology is realized through OPMT’s integrated manufacturing ecosystems.

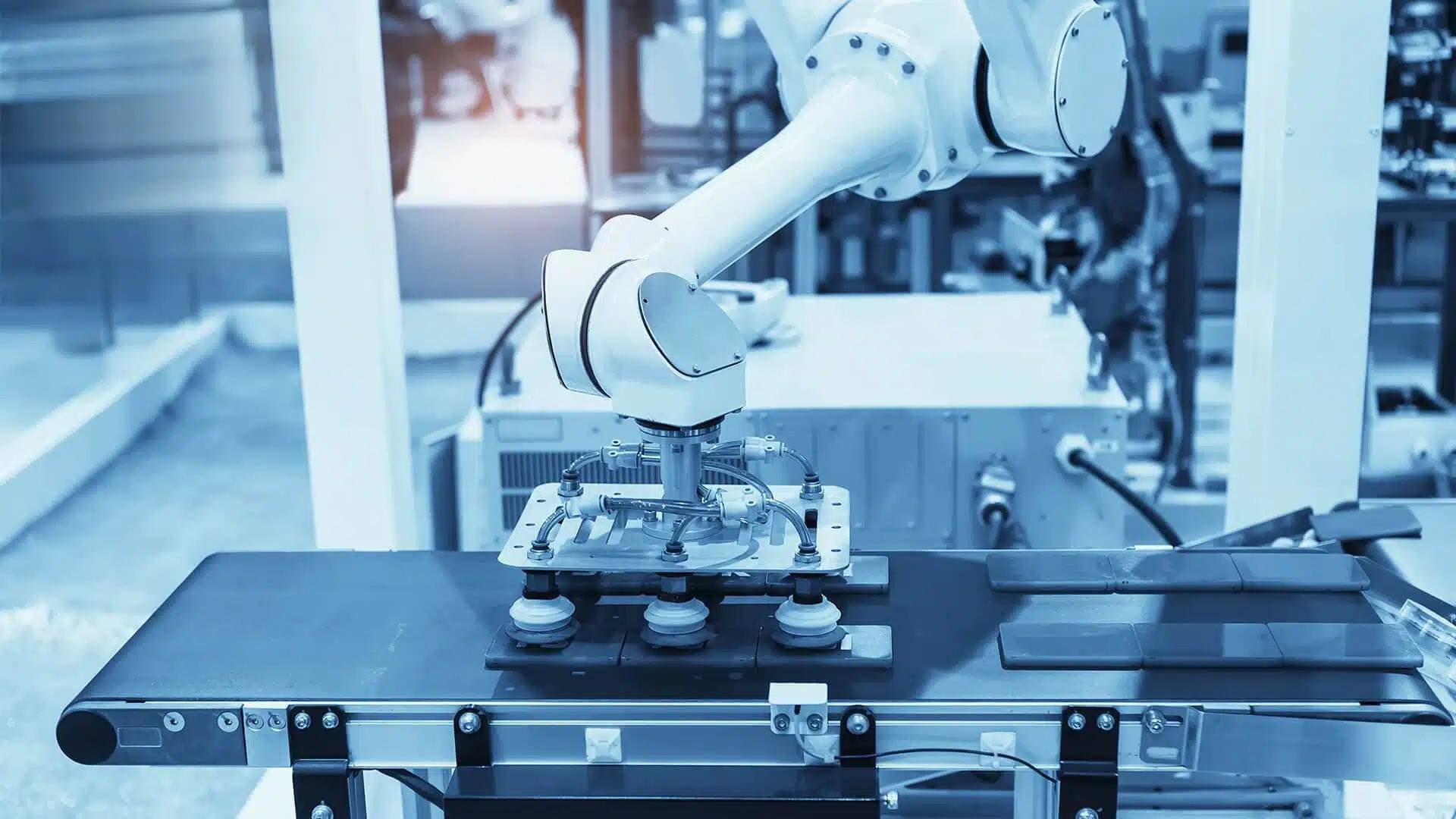

Comprehensive Factory Solutions: OPMT Laser specializes in creating fully integrated manufacturing systems that combine femtosecond laser technology with advanced CNC control, automated material handling, and inspection systems. The company’s iMTOS CNC control system with 13-axis sub-nanometer linkage interpolation algorithm enables seamless coordination of complex multi-axis movements, while the self-developed CAM software provides intuitive programming interfaces for complex 3D machining tasks.

Multi-Process Manufacturing Cells: The LightMUT 750V exemplifies OPMT’s integrated approach by combining laser grinding and milling in one machine, enabling complete part processing in a single setup. This integration reduces handling errors, improves dimensional accuracy, and significantly decreases production cycle times compared to conventional multi-machine approaches.

Industrial Digitalization and Automation: OPMT’s systems integrate seamlessly with Industry 4.0 environments through comprehensive data collection and process monitoring capabilities. The iMTOS CNC system features open architecture and modular design, allowing customization to specific manufacturing requirements while facilitating connectivity with factory management systems.

For a deeper understanding of how different laser technologies compare and which solution best suits your manufacturing challenges, explore our comprehensive guide to nanosecond, picosecond, and femtosecond lasers. To see how these technologies are applied in specific industries, visit our industrial application solutions page.

Have you ever imagined a technology so precise it could reshape the future of manufacturing and medicine? Femto lasers are doing just that. These lasers operate on timescales of quadrillionths of a second. Throughout this article, we’ve explored how femto lasers are used in everything from delicate eye surgery to advanced materials processing. Did you know their precision minimizes heat damage, making them ideal for intricate tasks?

As leaders in Innovative CNC Systems & Laser Processing Solutions, OPMT Laser is at the forefront of this revolution, offering solutions like the LightGrind LT20 or the Micro3D L530V. Interested in exploring how femto laser technology can revolutionize your projects? Discover the potential of femto lasers and how OPMT Laser can help you achieve unparalleled precision and efficiency in your applications.

Discover OPMT Laser’s ISO 9001-certified femtosecond-pulse CNC systems with sub-300 fs precision, ±0.003 mm tolerance, and AI-driven process control. Learn how top ultrafast-laser partnerships deliver 95% first-pass yields and < 12-month ROI in medical and microfabrication.

Guangdong Original Point Intelligent Technology Co., Ltd. (Original Point Intelligent), established in 2015, is a National Specialized and Innovative “Little Giant” Enterprise and National Intellectual Property Advantage Enterprise. The company

Light 5X 40V-I PCD 5-Axis Laser Machining Solution, premiering at EMO Hannover 2025! Date: 22-26 September 2025Venue: Messegelände, 30521 ,Hannover, Germany | Stand: Hall 4, E08 Following three years of intensive collaborative R&D, OPMT

Comprehensive 2025 guide to selecting the best 5-axis CNC machine. Technical specifications, ROI analysis, and expert recommendations for industrial applications.