Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Single-laser grinding machines are revolutionizing the precision machining landscape, addressing the growing demand for efficiency and accuracy in manufacturing. Did you know that laser technology can enhance grinding precision by up to 30%? This article promises to equip you with valuable insights into the operation of single-laser grinding machines, highlighting their significant advantages, potential limitations, and practical tips for effective use across various industries.

Whether you’re a seasoned professional or just starting your journey in machining, understanding these advanced tools can elevate your work. You’ll discover how to leverage this innovative technology to improve your processes and outcomes. Ready to unlock the potential of single-laser grinding machines? Let’s get started!

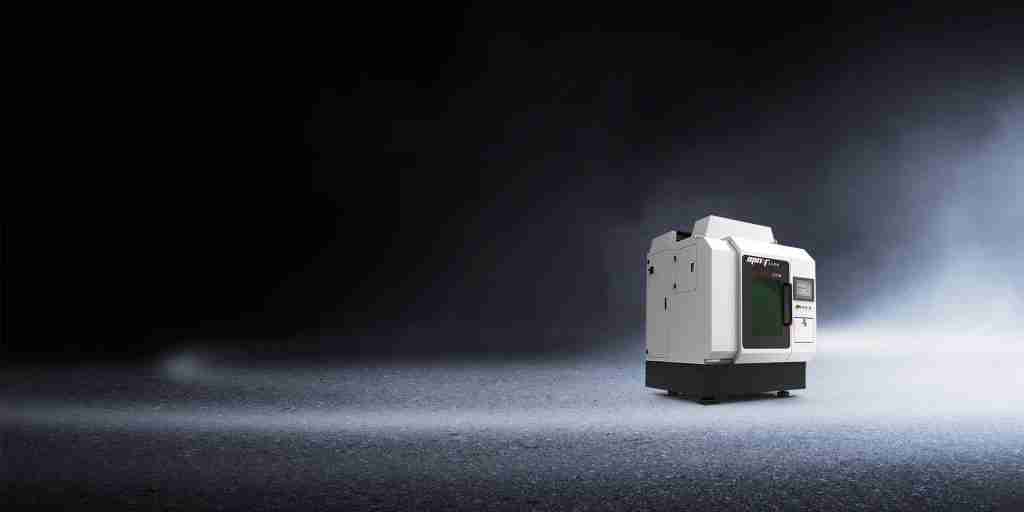

A single-laser grinding machine employs a concentrated laser beam to grind materials with exceptional precision. Unlike traditional grinding methods that rely on physical contact between the grinding wheel and the workpiece, this innovative technology uses thermal energy from the laser to remove material. This results in finer surface finishes and improved control over the grinding process.

Read More: Best 10 Single-laser Grinding Machine Suppliers

A single-laser grinding machine employs advanced laser technology for precise material removal, making it particularly effective for delicate components. This innovative approach minimizes mechanical wear and reduces the risk of damage, enhancing overall operational efficiency.

Core Components

Single-laser grinding technology is revolutionizing manufacturing processes across various sectors, offering distinct advantages that enhance productivity and precision. Here’s a concise overview of its key benefits and applications:

Despite their advantages, single-laser grinding machines come with certain limitations:

Single-laser grinding technology offers remarkable precision, surface quality, and versatility while reducing tool wear and supporting automation. However, potential users must weigh the initial investment, material compatibility, and necessary operator expertise to maximize the benefits in their manufacturing processes.

Single-laser grinding machines deliver significant cost-effectiveness in modern manufacturing, particularly in precision machining. While the initial investment can be high, ranging from tens of thousands to millions of dollars depending on power and features, the long-term operational costs are generally lower due to increased production efficiency and reduced material waste, enhancing the return on investment (ROI).

Operationally, these machines typically consume less power and incur lower maintenance costs compared to traditional equipment. The automation features of laser technology decrease reliance on manual labor, further reducing labor costs. Additionally, single-laser grinding machines can cut various materials quickly, significantly boosting production rates. Research indicates that operating costs for laser cutting can range from $4 to $20 per hour, while traditional methods may exceed $30.

However, potential limitations include challenges in cutting certain reflective materials and the need for skilled operators. Therefore, businesses should thoroughly assess their production needs, market potential, and long-term benefits before investing. Overall, single-laser grinding machines offer an efficient, low-consumption, and precise solution that is a worthy investment for many manufacturers.

Understanding the cost landscape for laser surface treatment systems is crucial for businesses and professionals in 2025. Prices vary widely based on equipment type, specifications, and capabilities. This guide breaks down the pricing for different laser technologies, from handheld units to industrial-scale systems.

Handheld laser cleaning devices start at $3,000 for basic models, with advanced high-power units reaching $16,000. Industrial-scale laser cleaning systems begin at $20,000 for entry-level equipment, while high-end models exceed $50,000. Fiber laser cutting machines range from $10,000 for entry-level units to over $30,000 for industrial-grade equipment. CO2 laser systems offer the broadest price range, starting at $2,000 for basic models and reaching six figures for top-tier industrial lasers.

Key factors influencing equipment costs include power output, work area size, automation features, brand reputation, laser type, material compatibility, additional features, and software capabilities. When budgeting, consider expenses beyond the initial purchase, such as installation, operator training, maintenance, and consumables. While high-end machines have steeper upfront costs, they often deliver better long-term value through improved efficiency, versatility, and durability.

| Laser Category | Entry-Level Price | High-End Price |

|---|---|---|

| Handheld Cleaning | $3,000 | $16,000 |

| Industrial Cleaning | $20,000 | $50,000+ |

| Fiber Cutting | $10,000 | $30,000+ |

| CO2 Systems | $2,000 | $100,000+ |

To optimize the use of single-laser grinding machines effectively, it’s crucial to adopt best practices that enhance performance and precision. Here are essential tips for maximizing efficiency:

By implementing these strategies, you can significantly enhance the efficiency and effectiveness of single-laser grinding machines, ensuring high-quality results while minimizing downtime and material waste.

A solid understanding of single-laser grinding machines is crucial for professionals in manufacturing sectors that demand high precision and quality. By leveraging this technology, industries can achieve superior results while minimizing costs associated with traditional machining methods. As advancements continue in laser technology, staying informed about new developments will be essential for maintaining competitive advantages in precision machining.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.