Lab diamond machines are advanced technological systems that create diamonds in controlled laboratory environments, replicating natural formation processes within a fraction of the time. These sophisticated apparatuses have revolutionized the diamond industry by offering sustainable and ethical alternatives to traditional mining.

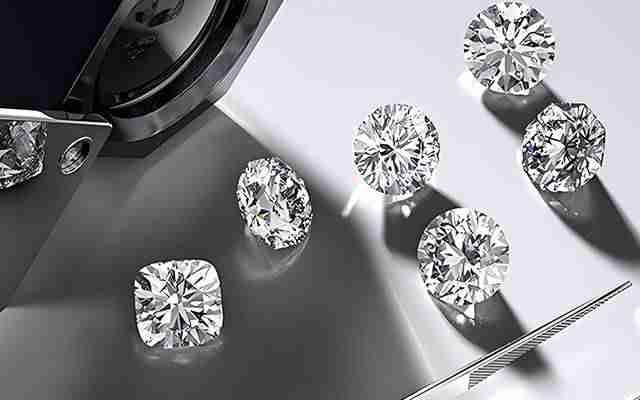

By 2025, advancements in lab diamond technology have significantly improved efficiency and quality, making synthetic diamonds virtually indistinguishable from their natural counterparts. This innovation has not only disrupted the jewelry market but also created new possibilities for industrial applications, particularly in cutting tools, electronics, and precision manufacturing industries.

What is a lab diamond machine?

A lab diamond machine is a sophisticated apparatus designed to produce synthetic diamonds with properties identical to natural diamonds. These devices utilize advanced technologies to replicate the extreme conditions found deep within the Earth, allowing carbon atoms to crystallize into diamond structures. The two primary types of lab diamond machines are:

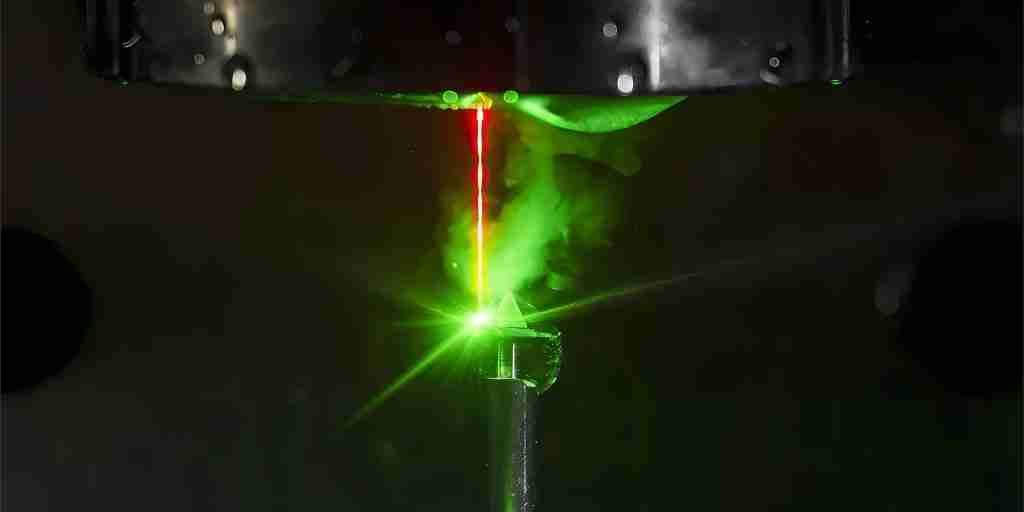

High Pressure High Temperature (HPHT) machines: These simulate the intense pressure and heat of the Earth’s mantle to form diamonds from carbon, creating synthetic diamonds that require precision finishing with specialized laser processing equipment.

Chemical Vapor Deposition (CVD) machines: These use carbon-rich gas and lower temperatures to grow diamonds layer by layer on a diamond seed. Advanced equipment like the DiaCUT L315V CVD Laser Diamond Surface Grinding Machine provides exceptional precision for finishing these lab-created diamonds, ensuring perfect surface quality for both industrial applications and gemstone production.

The manufacturing process for lab diamonds extends beyond initial creation to include crucial precision cutting, shaping, and polishing stages. Advanced five-axis laser systems like the Light 5X series laser machining centers offer the micron-level accuracy necessary for working with these superhard materials, achieving contour precision as fine as 0.015 mm for diamond tools and components.

Today’s lab diamond manufacturing ecosystem combines diamond creation technology with advanced laser processing equipment to produce genuine diamonds that are chemically, physically, and optically identical to their mined counterparts—but with greater customization potential and significantly lower environmental impact.

How lab diamond machines work

Lab diamond machines utilize two primary methods for creating synthetic diamonds: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Each method simulates the natural processes that form diamonds but does so in a controlled laboratory environment and produces materials requiring advanced processing technology for finishing.

High Pressure High Temperature (HPHT)

How HPHT Works:

Setup: A small diamond seed is placed inside a growth chamber along with a carbon source, typically graphite, and metal catalysts.

Extreme Conditions: The chamber is subjected to immense pressure exceeding 870,000 pounds per square inch and high temperatures ranging from 1,300°C to 1,600°C. This setup replicates the natural conditions found deep within the Earth where diamonds form.

Carbon Dissolution: Under these extreme conditions, the metal catalyst melts and dissolves the carbon source. The dissolved carbon then precipitates onto the diamond seed, gradually forming a synthetic diamond crystal.

Growth Period: This crystallization process can take several days to weeks, allowing the diamond to grow to the desired size. Once removed from the press, these diamonds require precision cutting and surface processing, often performed with specialized laser equipment like the Light 5X 40V Vertical 5-Axis Laser Machining Center, which offers micron-level accuracy critical for working with these superhard materials.

Characteristics of HPHT Diamonds:

- Typically exhibit fewer internal flaws compared to CVD diamonds

- Can be produced in various colors depending on the treatment applied after growth

- Require specialized laser processing for shaping and finishing once formed

Chemical Vapor Deposition (CVD)

How CVD Works:

Initial Setup: A thin diamond seed is placed in a sealed vacuum chamber.

Gas Introduction: The chamber is filled with a carbon-rich gas mixture, usually hydrogen and methane.

Heating and Plasma Creation: The chamber is heated to temperatures around 800°C to 1,200°C. Energy sources like microwaves break down the gas molecules into plasma.

Carbon Deposition: Carbon atoms from the plasma adhere to the diamond seed, building up layers of diamond crystal over time.

Growth Duration: The CVD process typically takes about 3-4 weeks for a diamond to form completely. After formation, the raw diamond plates require surface grinding and polishing using advanced equipment like the DiaCUT L315V CVD Laser Diamond Surface Grinding Machine, which provides exceptional precision for finishing these lab-created diamonds with perfect surface quality.

Characteristics of CVD Diamonds:

- Often have a brown tint due to internal strain but can undergo treatments to enhance color

- Generally produced at lower costs and energy requirements than HPHT diamonds

- May contain more internal inclusions requiring expert laser processing for flawless finishing

Post-Growth Processing of Lab Diamonds

Both HPHT and CVD diamonds require significant post-growth processing to achieve gem-quality or industrial-grade specifications. This critical stage involves precision cutting, surface grinding, and polishing—processes where OPMT Laser’s advanced 5-axis laser machining centers excel.

The transition from raw lab-grown diamond to finished product involves multiple stages of laser processing where accuracy to within microns is essential. Five-axis laser machining centers provide the precision necessary for working with these superhard materials, achieving contour precision as fine as 0.015 mm for both industrial applications and gemstone production.

Comparison of HPHT and CVD

| Aspect | HPHT Diamonds | CVD Diamonds |

|---|---|---|

| Formation Process | Mimics natural conditions with high pressure and temperature | Uses gas deposition in a vacuum chamber |

| Temperature & Pressure | High temperatures (1400-1600°C) & pressures (5-6 GPa) | Moderate temperatures (700-1200°C) & low pressure |

| Growth Time | Several days to weeks | About 3-4 weeks |

| Color Quality | Can produce colorless or treated colors | Often has brownish undertones; requires treatment for color enhancement |

| Internal Flaws | Fewer inclusions | More likely to have inclusions |

| Post-Processing Equipment | Requires specialized laser processing systems | Needs precision surface grinding machines |

Both methods produce diamonds that share the same physical and chemical properties as natural diamonds, making them indistinguishable without specialized equipment. The choice between HPHT and CVD often depends on specific requirements regarding quality, cost, and intended use, with each requiring particular types of laser processing equipment for optimal finishing results.

Benefits of Lab-Created Diamond Technology

Lab-created diamonds, also referred to as lab-grown or synthetic diamonds, have become increasingly popular due to their distinct advantages over traditionally mined diamonds. These benefits include affordability, ethical sourcing, environmental sustainability, and superior quality, all made possible through cutting-edge precision manufacturing technology.

Cost-Efficiency

One of the primary reasons consumers choose lab-created diamonds is their cost-effectiveness. The production of these diamonds typically costs 30-40% less than extracting natural diamonds from the earth. This significant reduction in cost is due to a more efficient supply chain and the elimination of expensive mining operations. Advanced lab diamond machines utilizing high-precision laser technology, such as the DiaCUT L315V CVD Laser Diamond Surface Grinding Machine, have revolutionized the finishing process, ensuring exceptional surface quality while maximizing production efficiency. Consequently, buyers can acquire larger and higher-quality gems at more accessible prices, making luxury items attainable for a broader audience.

Ethical Sourcing

Lab-created diamonds offer a responsible alternative to natural diamonds by ensuring ethical sourcing practices. The mining industry has often been associated with human rights abuses and the trade of conflict diamonds, commonly known as “blood diamonds.” In contrast, lab-grown diamonds are manufactured in controlled environments that uphold ethical labor standards. The production process employs sophisticated equipment like five-axis laser machining centers, which provide the micron-level precision necessary for creating flawless gem-quality diamonds. This manufacturing transparency allows consumers to purchase these gems without concerns about their origins or the risk of exploitation.

Environmental Sustainability

The environmental consequences of diamond mining are considerable, involving land disruption, habitat destruction, and significant carbon emissions. Lab-created diamonds, however, have a much smaller ecological footprint. Their production does not disturb land surfaces or generate mineral waste, making them a more sustainable option. Modern lab diamond machines use energy-efficient laser technology that minimizes resource consumption while maximizing output quality. This eco-friendly aspect resonates with environmentally conscious consumers who seek alternatives that align with their values.

Superior Quality and Customization

Lab-grown diamonds are often purer and of higher quality than their mined counterparts. The controlled conditions in which they are produced allow for precise adjustments to their characteristics, resulting in fewer imperfections and higher clarity ratings. Many lab-grown diamonds achieve Type IIa purity, which is rarely found in natural stones. The manufacturing process, which typically employs both HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition) methods, benefits significantly from advanced laser processing technology that can achieve contour precision as fine as 0.015 mm. Additionally, consumers can customize lab-created diamonds in terms of size, color, and quality to meet their specific preferences.

Lab-created diamond technology provides significant advantages that make them an appealing choice for those seeking beauty without compromising on ethics or environmental considerations. With lower costs, ethical sourcing practices, reduced ecological impact, and superior quality options available for customization, lab-grown diamonds represent a contemporary choice in the jewelry market.

Applications of Synthetic Diamond Systems

Synthetic diamonds, also known as lab-grown diamonds, are increasingly recognized for their versatility and unique properties across various industries. Their applications span jewelry, industrial tools, scientific research, and more, making them significant materials in modern technology and consumer goods.

Jewelry Industry

The jewelry sector has experienced a notable shift towards synthetic diamonds, particularly in engagement rings and fine jewelry. These lab-grown alternatives provide:

- Cost Efficiency: Lab-grown diamonds are generally more affordable than natural diamonds, offering cost-effective options for consumers.

- Sustainability: As ethical concerns regarding diamond mining grow, synthetic diamonds present a sustainable alternative. They are produced in controlled environments, minimizing environmental impact and avoiding issues related to conflict diamonds.

- Visual Similarity: Lab-grown diamonds possess the same physical and chemical properties as natural diamonds, ensuring they are visually indistinguishable to the naked eye.

This combination of factors drives the popularity of synthetic diamonds in the jewelry market, appealing to eco-conscious consumers seeking luxury without compromising on ethics or aesthetics.

Industrial Tools

Synthetic diamonds are extensively used in various industrial applications due to their exceptional hardness and thermal conductivity. Key uses include:

- Cutting Tools: They are essential for manufacturing cutting blades, drills, and grinding wheels used in machining hard materials such as metals and ceramics. Their durability leads to longer tool life and reduced operational costs.

- High-Power Electronics: In electronics, synthetic diamonds serve as heat sinks for high-power devices, effectively managing heat dissipation. This is crucial since overheating is a common cause of electronic failures.

- Abrasives: Synthetic diamond abrasives are employed in construction materials and precision cutting applications, enhancing performance in tasks requiring high accuracy.

Scientific Research

In scientific domains, synthetic diamonds have emerged as valuable tools:

- Quantum Computing: Their unique properties make them suitable for applications in quantum technologies, including secure quantum communication systems.

- High-Pressure Experiments: Researchers utilize synthetic diamonds in experiments that require extreme conditions, benefiting from their robustness and stability under pressure.

- Medical Instruments: Synthetic diamonds are used in medical devices such as diamond-coated surgical tools that offer precision and durability during delicate procedures.

Abrasives and Precision Cutting

Synthetic diamond technology plays a critical role in producing abrasives for various industries:

- Construction: They are utilized for cutting and polishing hard materials, significantly improving efficiency and precision in construction projects.

- Precision Engineering: In high-tech manufacturing sectors, synthetic diamond tools provide ultra-sharp cutting edges essential for producing microelectronics and optical components with tight tolerances.

The diverse applications of synthetic diamond systems highlight their importance across multiple sectors. As technology advances and sustainability becomes increasingly prioritized by consumers and industries alike, the role of synthetic diamonds is expected to expand further, driving innovation and efficiency across various fields.

Practical Tips for Using Lab Diamond Machines

Understanding the machinery and processes involved in producing lab-grown diamonds is essential for achieving high-quality results. Here are practical tips to optimize the use of lab diamond machines effectively.

Choose the Right Method

Selecting the appropriate synthesis method is crucial when producing lab-grown diamonds. The two primary methods are:

High Pressure High Temperature (HPHT): This method simulates the natural conditions under which diamonds form, using extreme pressure and temperature to crystallize carbon into diamonds. It is particularly effective for producing colored diamonds and can enhance the color of lower-grade stones. After formation, these diamonds require precision finishing with specialized laser processing equipment like the Light 5X 40V Vertical 5-Axis Laser Machining Center, which offers micron-level accuracy critical for working with these superhard materials.

Chemical Vapor Deposition (CVD): This method involves placing a diamond seed in a chamber filled with carbon-rich gas. The gas is heated, allowing carbon atoms to deposit onto the seed and grow into a diamond. CVD is increasingly popular for producing larger, higher-quality colorless stones due to its efficiency and control over growth parameters. For optimal surface quality, the DiaCUT L315V CVD Laser Diamond Surface Grinding Machine provides exceptional precision for finishing these lab-created diamonds, ensuring perfect surface quality for both industrial applications and gemstone production.

Both methods yield authentic diamonds with identical physical and chemical properties to natural diamonds, catering to different market needs and preferences. The post-synthesis processing stage is equally critical, requiring specialized laser technology to achieve the desired cut, clarity, and finish.

Implement Quality Control Measures

To ensure that the diamonds produced meet industry standards, rigorous quality control is essential. Key measures include:

Regular Calibration: Machines should be calibrated frequently to maintain precision in diamond growth and processing, ensuring consistent results. Five-axis laser machining centers typically include advanced calibration systems that help maintain the exceptional accuracy needed when working with diamond materials.

Post-Production Inspections: Conduct thorough inspections assessing clarity, color, and cut quality to meet grading standards. High-resolution optical systems integrated into modern laser processing equipment facilitate detailed examination of finished diamonds.

Advanced Detection Equipment: Utilize specialized imaging and spectroscopic technologies that can accurately differentiate between lab-grown and natural diamonds, enhancing consumer trust. These technologies can be seamlessly integrated with laser processing systems to create a comprehensive quality control workflow.

Maintain Transparency in Production

Building consumer trust requires transparency regarding your products. Important practices include:

Certification: Provide certificates detailing the diamond’s creation process (HPHT or CVD) along with its characteristics. This helps consumers understand the origin of their purchase and the precision technology used to create it.

Education on Sustainable Manufacturing: Inform consumers about the environmental advantages of lab-grown diamonds compared to mined alternatives, emphasizing their sustainable production methods and the precision laser technology used to create perfect finishes without generating additional waste.

Stay Informed on Technological Advancements

The field of lab-grown diamonds is rapidly evolving, making it important to stay updated on technological advancements that can enhance production efficiency and product quality. Consider:

Industry Conferences and Workshops: Attend events focused on diamond technology to learn about new techniques and innovations in laser processing equipment for diamond finishing.

Follow Reputable Sources: Subscribe to publications that cover advancements in diamond synthesis methods and laser machinery capabilities for post-production processing.

Engage with Professional Networks: Participate in forums where industry experts share insights and experiences related to lab diamond production and precision finishing techniques.

By implementing these practical tips, individuals involved in the production or purchase of lab-grown diamonds can optimize their operations, ensure high-quality output, and foster consumer confidence in their products.

Conclusion

Lab diamond machines represent a significant technological achievement in gemstone production. They offer an ethical and sustainable alternative to mined diamonds, producing gems that are chemically identical to their natural counterparts. As technology continues to advance, we can expect further improvements in the efficiency and capabilities of these remarkable machines.

For those interested in learning more about the diamond industry, consider exploring topics such as “How do lab-grown diamonds compare to natural diamonds in terms of quality?“

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.