Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

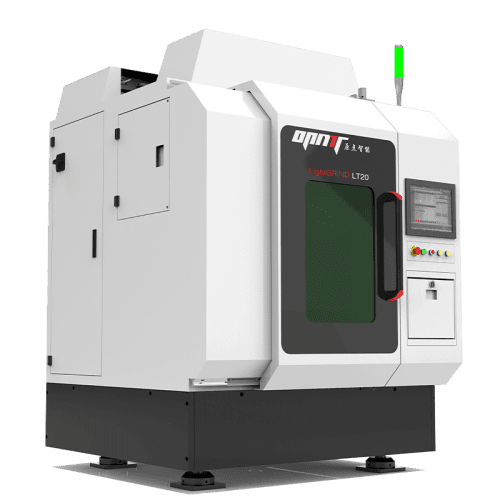

LightGRIND LT20 Dual-laser Grinding Machine revolutionizes precision manufacturing with integrated rough and fine processing. Its innovative turntable fixture processes up to 26 workpieces simultaneously, reducing processing time by 70%. Featuring a 500W fiber laser and high-precision CNC control, it delivers mirror-finish results in just 5 hours.

Please fill in your contact information to download the PDF.