Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

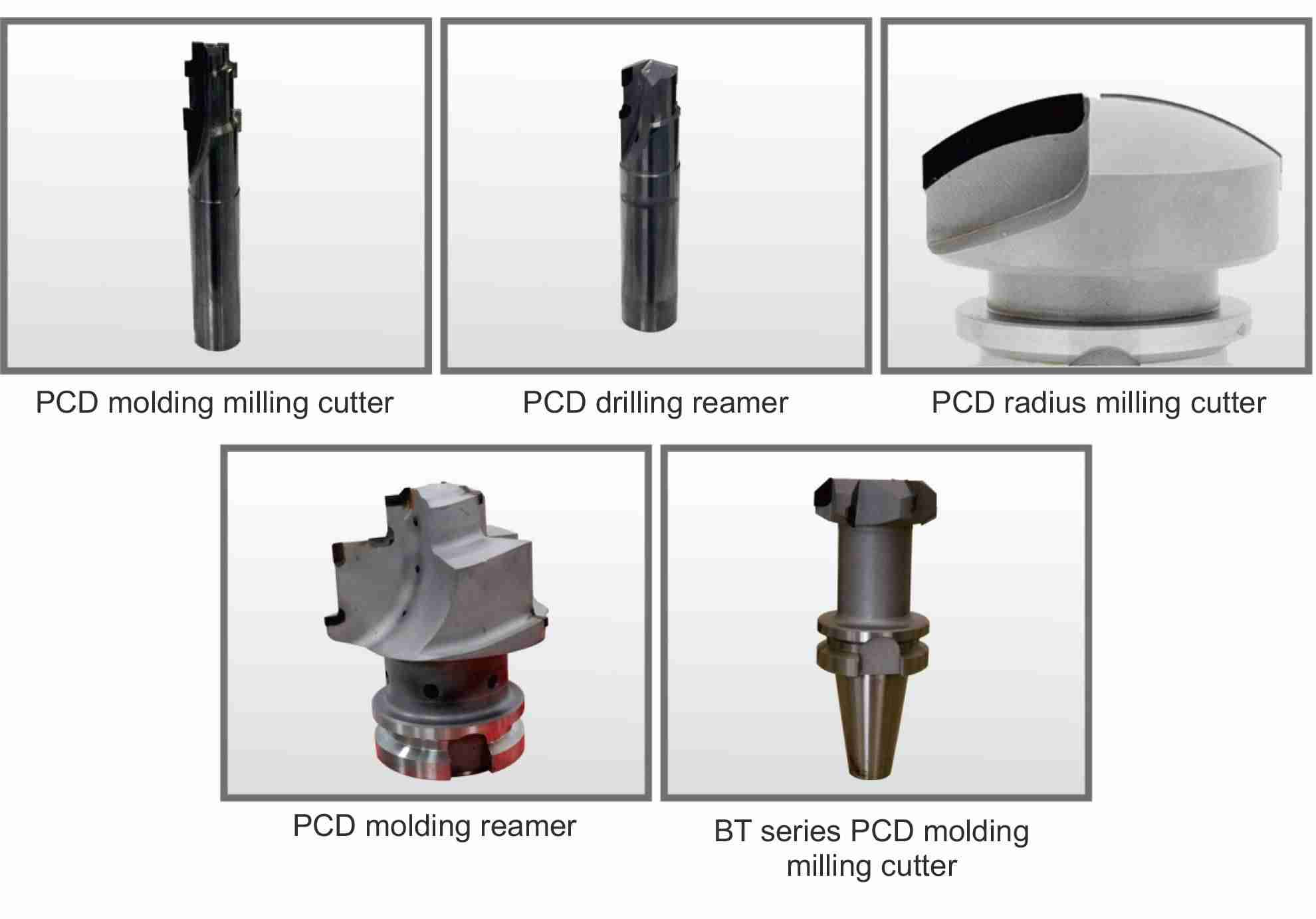

Light 5X 60V Vertical 5-Axis Laser Machining Center revolutionizes PCD/PCBN/CVD tool finishing with astonishing 0.003mm accuracy. It delivers 200% faster processing than EDM at 50% lower costs, ideal for automotive and 3C electronics industries. This innovative system combines NUM CNC controls with GTR software for seamless one-setup processing, transforming precision manufacturing.

The Light 5X 60V vertical 5-axis laser machining center is a precision CNC laser machine self-developed and designed by Guangdong Original Point Intelligent Technology Co., Ltd for high-precision machining of workpieces with large-curvature surfaces and complex contours. It can be applied in areas such as 3C, aerospace, mold, automobile, military, education, and scientific research. This machine is widely used for machining of automotive tools, PCD, CBN, hard alloys, ceramics, metal and other materials for machining of workpieces with complex contours and profiles, such as superhard materials, hard alloys, superhard coatings and ceramic complex profile tools when it is used with the dedicated machining software.

Please fill in your contact information to download the PDF.