Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

Explore innovative solutions for the automotive industry, including advanced CNC machines and laser processing techniques, to enhance efficiency and quality!

Key Takeaways:

The automotive industry demands precision, efficiency, and innovation. At OPMT Laser, we provide cutting-edge CNC systems and laser machine tools designed to meet these rigorous demands. Our solutions are tailored to enhance the manufacturing processes for a wide array of automotive components, ensuring top-tier quality and performance. Having spent years in this field, I’ve seen firsthand how the right technology can transform production lines, reducing waste and improving overall output.

Laser technology has revolutionized the way automotive parts are manufactured. From cutting intricate designs to welding with pinpoint accuracy, lasers offer unparalleled precision.

One example I always share is how a leading automotive manufacturer improved their chassis welding process by 40% simply by switching to laser welding. It’s not just about speed; it’s about the quality and consistency that these technologies bring.

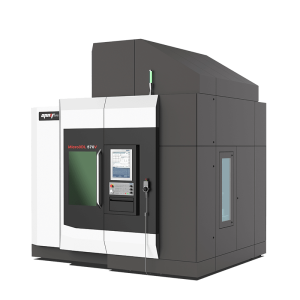

The 5-Axis Laser Machining Center represents the pinnacle of precision manufacturing. These machines can create complex geometries and intricate designs, making them essential for producing high-performance automotive parts.

For instance, the Light 5X 60V Vertical 5-Axis Laser Machining Center from OPMT Laser is engineered to deliver exceptional performance and accuracy. This machine is perfect for creating intricate components such as turbine blades, gears, and custom engine parts.

Our laser and CNC solutions cater to diverse applications within the automotive sector.

One of our clients, a manufacturer of high-end sports cars, uses our systems to create custom exhaust systems. The precision and speed of our lasers allow them to produce these parts on demand, meeting the unique needs of their customers.

OPMT Laser offers a range of products tailored for the automotive industry. Here’s a brief look at some of our standout machines:

Choosing the right partner for your manufacturing needs is critical. Here’s why OPMT Laser stands out:

From my perspective, it’s not just about selling machines; it’s about building long-term partnerships. We work closely with our clients to understand their challenges and provide solutions that drive their success.

The future of automotive manufacturing is inextricably linked to advancements in laser technology. As electric vehicles and autonomous driving become more prevalent, the demand for precision-engineered components will only increase. OPMT Laser is committed to staying ahead of these trends, providing innovative solutions that empower our clients to thrive in this evolving landscape. I am personally excited to see how these technologies continue to shape the industry and drive new possibilities.

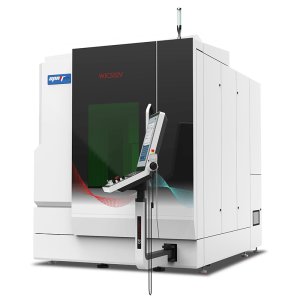

WJC532V Water-guided Laser Five-axis Machining Center revolutionizes cutting and drilling for complex parts. Its water beam fiber technology achieves exceptional precision on super-hard materials, with a 100:1 cutting depth-to-width ratio and ±3μm accuracy. This versatile system delivers unparalleled surface quality for automotive and electronics manufacturing, setting new industry standards.

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L530V five-axis femtosecond laser machining center delivers unparalleled precision for 3D complex structures. With ≤±10μm accuracy and <1μm material removal, it excels in automotive and 3C electronics applications. This innovative system combines self-developed software with 40W infrared femtosecond laser technology, revolutionizing micro-nano processing and fine mold texturing.

L03A Oil Bit Contour Laser Machine revolutionizes PCD composite sheet processing with its self-developed CNC system. Featuring automatic loading for up to 100 pieces and a retractable dust-sealing structure, it ensures precision contour processing while minimizing thermal damage, ideal for automotive and electronics manufacturing.

Please fill in your contact information to download the PDF.