Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

Need precise medical components? This guide covers CNC machining, laser tech, materials, and OPMT Laser’s specialized processing solutions.

Key Takeaways

The medical industry demands components with unparalleled precision and reliability. These components often form the backbone of life-saving devices and intricate surgical instruments. Achieving the required tolerances and surface finishes necessitates advanced manufacturing techniques.

Expert Insight: When selecting a processing solution, consider the entire lifecycle of the component. Can the solution handle prototyping, small-batch production, and high-volume manufacturing? This scalability is crucial for long-term success.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a workpiece to create the desired shape. In the realm of medical components, CNC machining offers exceptional precision, repeatability, and the ability to create complex geometries.

Expert Anecdote: I once worked on a project involving the manufacturing of a titanium spinal implant. The intricate design required a 5-axis CNC machine to create the complex curves and undercuts. The precision of the CNC machine ensured a perfect fit and optimal patient outcome.

Laser technology offers a non-contact approach to medical component processing, providing unique advantages in terms of precision, speed, and material versatility. From cutting and welding to marking and surface treatment, lasers are transforming the way medical components are made.

Expert Tip: When using lasers for medical component manufacturing, safety is paramount. Always ensure proper laser safety training, protective equipment, and adherence to laser safety regulations. And remember, for certain materials, explore PCD laser cutting machine suppliers for specialized needs.

OPMT Laser specializes in developing advanced CNC systems and laser machine tools tailored for precision medical components processing. Their solutions are designed to meet the demanding requirements of the medical industry, offering exceptional precision, reliability, and versatility.

Final Thought: The manufacturing of precision medical components is a complex and demanding field. By partnering with a technology provider like OPMT Laser, medical device manufacturers can gain access to the advanced solutions and expertise needed to succeed in this critical industry. Also, for those considering expanding their capabilities, exploring the best laser CNC machining center suppliers can provide valuable insights.

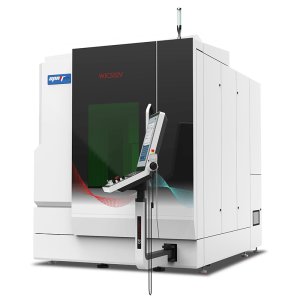

WJC532V Water-guided Laser Five-axis Machining Center revolutionizes cutting and drilling for complex parts. Its water beam fiber technology achieves exceptional precision on super-hard materials, with a 100:1 cutting depth-to-width ratio and ±3μm accuracy. This versatile system delivers unparalleled surface quality for automotive and electronics manufacturing, setting new industry standards.

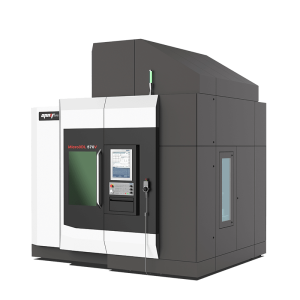

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L530V five-axis femtosecond laser machining center delivers unparalleled precision for 3D complex structures. With ≤±10μm accuracy and <1μm material removal, it excels in automotive and 3C electronics applications. This innovative system combines self-developed software with 40W infrared femtosecond laser technology, revolutionizing micro-nano processing and fine mold texturing.

L03A Oil Bit Contour Laser Machine revolutionizes PCD composite sheet processing with its self-developed CNC system. Featuring automatic loading for up to 100 pieces and a retractable dust-sealing structure, it ensures precision contour processing while minimizing thermal damage, ideal for automotive and electronics manufacturing.

Please fill in your contact information to download the PDF.