Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

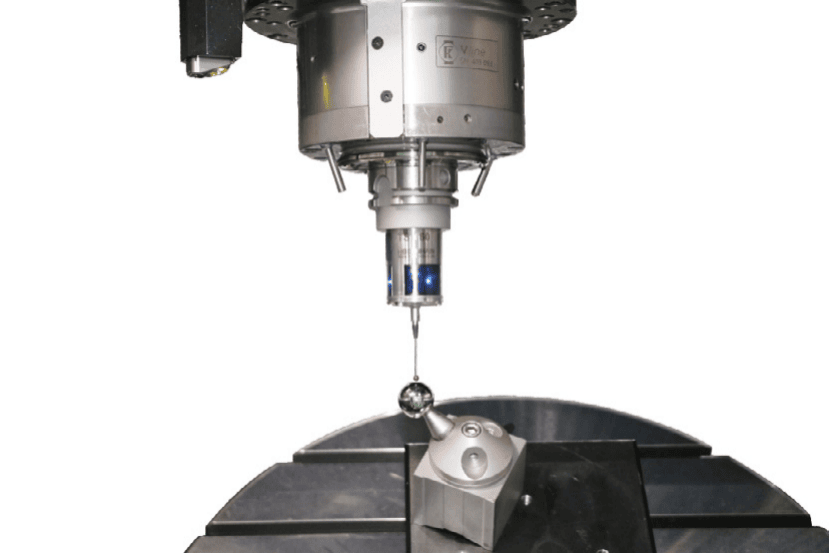

Are you curious about the inner workings of machine tools and their diverse applications? OPMT Laser, a leader in multi-axis CNC systems and laser CNC machine tools, is here to demystify the world of machine tool operating principles and classification. Did you know that the global machine tool market is projected to reach $95.2 billion by 2027? In this guide, you’ll discover the fascinating mechanics behind these essential manufacturing devices and learn how to distinguish between various types. From our cutting-edge 5-axis vertical machining centers to innovative laser grinding machines, we’ll explore how these tools are shaping the future of industry. Get ready to unlock the secrets of machine tools and revolutionize your manufacturing processes!

Machine tools function on the fundamental concept of material removal to create precise shapes and dimensions. This process relies on two critical elements: generatrix and directrix. The generatrix (G) represents the cutting motion, while the directrix (D) represents the feed motion. In turning operations, for instance, G corresponds to the work’s cutting motion, and D to the tool’s feed motion.

Three essential types of motion drive machine tool operations:

These motions work in tandem to achieve precise material removal. For example, in OPMT Laser’s 5-axis vertical machining centers, the cutting motion removes material while the feed motion guides the tool along the workpiece surface.

The generation of surfaces on a workpiece follows specific principles:

Understanding these principles is crucial for optimizing machining processes and achieving high-precision results. OPMT Laser’s advanced laser grinding machines leverage these principles to deliver exceptional surface finishes and dimensional accuracy.

Industrial machining equipment is systematically categorized to align with modern manufacturing demands. Below is the updated 2025 framework, incorporating technical advancements and industry-specific applications:

Core categorization based on material removal mechanisms:

Movement flexibility determines part complexity:

| Axes | Motion Capability | Precision Tolerance | Industry Applications |

|---|---|---|---|

| 2 | X/Y linear | ±0.05 mm | Sheet metal brackets, signage engraving |

| 3 | X/Y/Z linear | ±0.01 mm | Pump housings, gearbox casings |

| 5 | 3 linear + 2 rotary (A/C) | ±0.005 mm | Dental implant abutments, turbine blade roots |

| 7+ | Synchronized multi-tool | ±0.003 mm | Automotive die-cast prototypes (OPMT QM-7H) |

Automation levels dictate production efficiency:

Specialization drives equipment design:

OPMT Laser specializes in multi-axis CNC systems and laser machine tools, providing innovative manufacturing solutions for industries requiring high precision and efficiency. Did you know the global market for 5-axis CNC machines is projected to reach $627.3 million by 2025? By integrating advanced motion control with laser cutting, OPMT enables manufacturers to tackle complex geometries and reduce production cycles by up to 40%.

OPMT’s multi-axis CNC systems excel in automotive, 3C electronics, and precision mold manufacturing. Their 5-axis vertical machining centers achieve ±0.003 mm accuracy, enabling intricate part production in a single setup. These systems integrate NUM Flexium+ CNC platforms for real-time toolpath adjustments, minimizing errors and material waste.

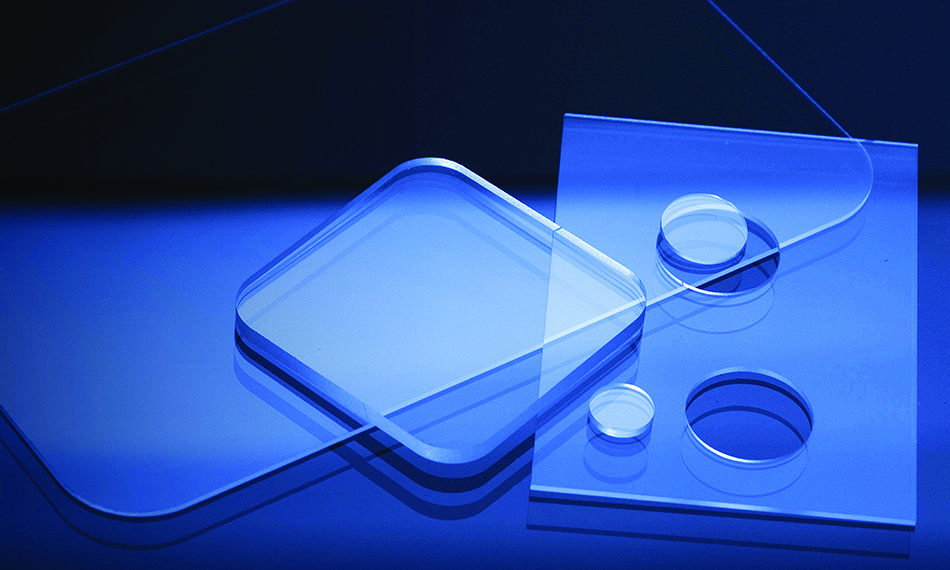

Laser machine tools like the LightGrind LT20 combine ultrafast lasers with adaptive optics for precision tasks such as PCD tool machining and mold texturing. This technology reduces post-processing needs by 60%, delivering mirror-like finishes on metals and composites.

| Feature | Multi-Axis CNC Systems | Laser Machine Tools |

|---|---|---|

| Precision | ±0.003 mm positional accuracy | Sub-micron surface finishes |

| Speed | 50% faster cycle times vs. 3-axis | 200% faster than EDM cutting |

| Applications | Complex automotive molds, 3C connectors | PCD tools, textured surfaces |

OPMT’s integrated approach addresses evolving manufacturing demands:

By merging CNC precision with laser versatility, OPMT empowers manufacturers to overcome traditional machining limitations. Explore their full product range to discover how these technologies can transform your production workflow.

Now that you’ve explored the fascinating realm of machine tool operating principles and classification, you’re better equipped to make informed choices for your manufacturing needs. Did you know that companies using advanced CNC machines can reduce production time by up to 50%? OPMT Laser’s cutting-edge multi-axis CNC systems and laser machine tools are designed to boost your productivity and precision. Ready to revolutionize your manufacturing process? Discover how OPMT Laser’s innovative solutions can help you stay ahead in today’s competitive market. Visit our product catalog to find the perfect machine for your unique requirements and take the next step towards manufacturing excellence.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

CO2 lasers cannot cleanly cut glass due to thermal stress. Discover why glass cracks and explore UV & femtosecond laser solutions for precision cutting.

Compare femtosecond and nanosecond laser micromachining for 5-axis manufacturing. Learn how ISO 9001- and FDA-ready OPMT systems control HAZ, tolerances and surface integrity in medical, semiconductor and diamond applications.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Please fill in your contact information to download the PDF.