Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Unlock the full potential of your projects with the right laser cutter power tailored to your specific applications. Whether you’re cutting through wood, metal, or plastic, understanding the power requirements is crucial for achieving precision and efficiency. Did you know that laser cutters can operate anywhere from 10W for paper to over 6000W for thick metals?

In this guide, OPMT Laser will illuminate the key factors that influence laser cutter power and how it impacts your results. You’ll learn about power measurement, the variables at play, and why selecting the appropriate wattage is vital for your success. Get ready to elevate your cutting and engraving skills as we break down everything you need to know!

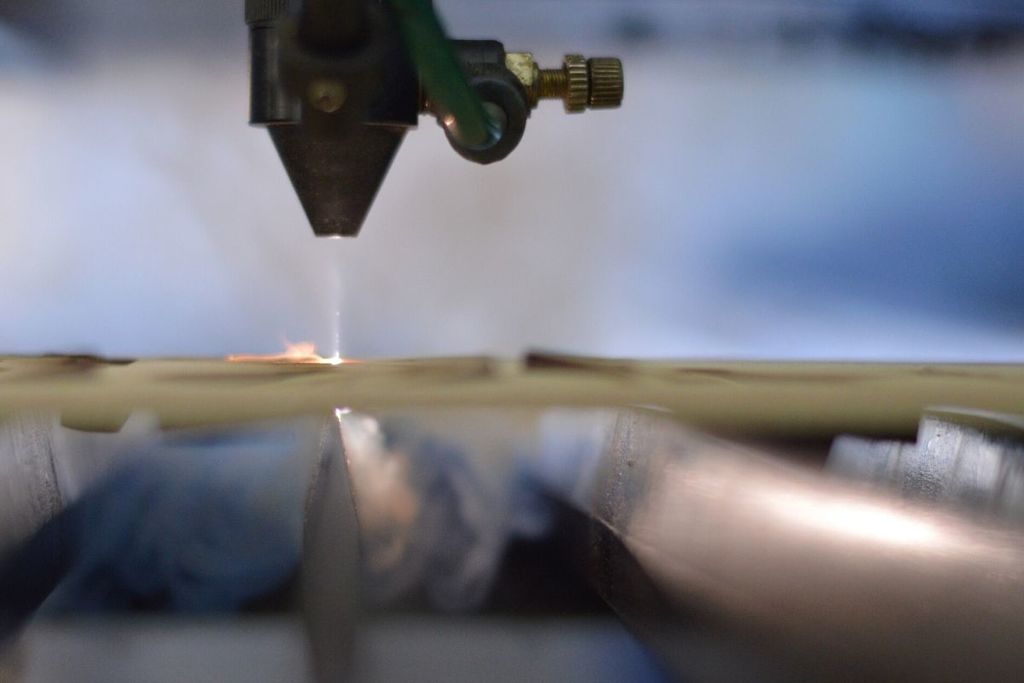

Laser cutting technology employs a highly focused beam of light to cut or engrave materials with exceptional precision. This method stands apart from traditional cutting techniques that utilize sharp blades. The term LASER is an acronym for Light Amplification by Stimulated Emission of Radiation, which encapsulates the fundamental principles behind this innovative process.

The laser beam is generated within a specialized tube filled with gases, typically carbon dioxide. When an electrical current passes through these gases, it excites the molecules, producing a powerful beam of light. This light is then directed through a series of mirrors that converge the beam into a single point at the laser head.

Modern laser cutters are equipped with Computer Numerical Control (CNC) systems, enhancing their functionality and precision:

Laser cutting technology is widely used across various industries due to its numerous advantages:

Understanding the factors that influence the effectiveness of laser cutters is essential for achieving optimal cutting results. The primary elements include wattage, beam quality, and wavelength. Each of these components plays a crucial role in determining how well a laser cutter can perform across different materials.

The wattage of a laser cutter is a critical factor that dictates its cutting ability. Measured in watts (W), higher wattage allows for cutting thicker materials at increased speeds. For example, a 2000W laser cutter can efficiently slice through 1mm thick steel at rates of 25.0 to 31.0 m/min. However, with higher power comes the need for enhanced cooling systems and potentially higher operational costs.

Beam quality is another significant factor impacting laser cutting performance. It refers to how well the laser beam can be focused and controlled, typically measured by the M² factor; lower values indicate better beam quality.

The wavelength of the laser light significantly affects how different materials absorb energy during the cutting process.

Laser cutters are primarily classified into two types based on how the laser beam is generated: CO2 laser cutters and fiber laser cutters. Each type has unique power levels and functionalities tailored to different materials and applications. Understanding these distinctions is crucial for selecting the right laser cutter for your specific needs.

CO2 laser cutting machines utilize a mixture of gases, including carbon dioxide, helium, and nitrogen. These gases are energized through electrical discharge, resulting in a laser beam with a wavelength of 10.6 micrometers. This wavelength makes CO2 lasers particularly effective for cutting non-metal materials such as wood, acrylic, and textiles. Interestingly, high-powered CO2 lasers can also handle some metal cutting tasks.

CO2 lasers are categorized into three main groups based on their power consumption:

Fiber laser cutters, often referred to as solid-state lasers, use a doped fiber optic cable as the active medium for generating the laser beam. This technology has evolved significantly, allowing fiber lasers to cut reflective metals like aluminum and copper with remarkable efficiency. They typically operate at twice the speed of CO2 lasers while being versatile enough to handle various organic materials.

Fiber lasers can be classified into three primary types based on their operational characteristics:

Understanding the types of laser cutter power is essential for making informed decisions when selecting a laser cutting solution. Whether you require a CO2 or fiber laser cutter, OPMT Laser provides innovative CNC systems and laser processing solutions tailored to meet diverse industrial needs. For more information on our products, explore our offerings like the Micro 3D Laser Cutter or the LP550V Laser Cutter.

Choosing the right laser cutter power is essential for achieving efficient and high-quality results tailored to your specific applications. This guide will explore the various power ranges available in laser cutters, how to determine the appropriate power for different materials and thicknesses, and examples of applications along with their ideal laser cutter power.

Laser cutters are available in a wide range of power outputs, typically from 10W to over 6,000W. Here’s a breakdown of the power ranges and their ideal applications:

Selecting the appropriate laser cutter power involves considering several factors such as material type, thickness, desired finish, and the specific capabilities of the laser cutter.

For materials like paper, cardboard, and thin plastics, a laser cutter power between 20W to 100W is generally sufficient. Higher power levels may cause burning or melting of these delicate materials. CO2 laser cutters are typically recommended for these applications due to their effectiveness in handling non-metallic materials.

When working with thicker materials such as metals, the required laser cutter power varies based on thickness:

For deep cuts in thick metals, fiber laser cutters are often the best solution due to their efficiency and precision.

Different industries utilize various types of laser cutters based on their specific needs:

Selecting the right laser cutter power is critical for optimizing performance across various applications. By understanding material types, thicknesses, and desired outcomes, you can make informed decisions that enhance efficiency and quality in your cutting projects. At OPMT Laser, we provide expert guidance to help you choose the ideal laser cutter tailored to your specific needs.

In laser cutting, two fundamental parameters are critical: power and cutting speed. Power refers to the energy output of the laser beam per unit time, while cutting speed indicates how quickly the laser moves across the material being cut.

While power and speed are technically independent variables, they are closely related in practice. Adjusting one often requires a corresponding change in the other to maintain optimal cutting performance. For example, a high-powered laser generates more energy per second. If this type of laser operates at a low cutting speed, it risks overheating and damaging the workpiece unless a deep cut is desired. Conversely, higher power typically necessitates higher cutting speeds to prevent excessive heat buildup.

To achieve the best results in laser cutting, it’s essential to optimize both power and speed settings based on the material type and thickness. Here are some guidelines:

When setting up a laser cutter, consider these factors:

By understanding the intricate relationship between power and speed in laser cutting, operators can make informed adjustments to optimize their processes, ensuring high-quality results tailored to their specific applications.

Laser cutter power density is a key factor that determines the efficiency and effectiveness of laser cutting machines. It quantifies the amount of laser power delivered to a specific area of material being processed. This measurement is crucial because it directly influences both the speed and quality of the cuts made by the laser.

Mathematically, power density is defined as the ratio of laser power to the cross-sectional area or spot size of the laser beam, expressed in watts per square millimeter (W/mm²). The formula for calculating power density is:

$$

\text{Power Density} = \frac{\text{Power}}{\pi \times \left(\frac{\text{Spot Size}}{2}\right)^2}

$$

For instance, if a laser cutter operates at 500 watts with a spot size of 0.2 mm, the power density would be approximately 198,943 W/mm². This high power density indicates that the laser can effectively cut through materials with precision and speed.

High laser cutter power density is essential in various applications where precision and quick processing are paramount. Here are some notable areas where this capability is utilized:

By leveraging high power density, manufacturers can enhance productivity while maintaining high standards of quality in their products. OPMT Laser’s innovative CNC systems and laser processing solutions are designed to optimize these parameters, ensuring users achieve optimal results in their cutting applications. For more information on our advanced laser solutions, explore our product offerings such as Micro3D L530V and LP550V.

When selecting a cutting machine with varying power, several critical factors come into play, including material type and thickness, cutting speed, and precision requirements. Understanding these elements ensures that you choose the right machine for your specific needs.

Different materials exhibit unique cutting properties, necessitating specific laser cutters and power levels. For instance, thicker materials demand higher-powered laser cutters, while thinner materials can be effectively processed with lower power options. It is crucial to select a laser-cutting machine that is tailored to the material type you intend to work with. For example, if your projects involve metal, consider specialized machines like the OPMT Laser LP550V designed explicitly for metal cutting.

The cutting speed refers to how quickly the laser cutter traverses the material being processed. While higher power may allow for increased speed, it is vital to balance this with the quality of the cut. A faster cutting speed can lead to reduced precision if not managed correctly. Therefore, understanding the optimal speed for your chosen material and desired finish is essential.

Precision is another significant factor when choosing a cutting machine. The level of detail required in your cuts will influence both the speed and power settings of your laser cutter. Typically, higher precision requires slower speeds and more power. Conversely, if your project tolerates lower precision, you may opt for faster speeds with less power. This balance is crucial for achieving the best results tailored to your specific applications.

Cost plays a vital role in establishing a laser-cutting setup. Generally, high-powered lasers come at a premium compared to lower-powered alternatives. Additionally, fiber laser machines often have a higher price point than CO2 models due to their advanced capabilities and efficiencies. When budgeting for your cutting machine, factor in not only the initial purchase price but also long-term operational costs associated with maintenance and consumables.

Selecting the right cutting machine involves careful consideration of various factors such as material type, thickness, cutting speed, precision requirements, and cost. By understanding these elements, you can make an informed decision that aligns with your operational needs and budget constraints. For more information on specific products that suit different applications, explore our offerings at OPMT Laser.

One of the most common misconceptions is that higher power always leads to better cutting results. This is misleading. The effectiveness of a laser cutter is highly dependent on the material being processed. For example, using a high-powered fiber laser to cut paper or wood is unnecessary and inefficient—imagine trying to slice an apple with a saw instead of a knife. Selecting the right power level tailored to the specific material ensures optimal performance and cost-effectiveness. Understanding your project’s requirements is essential for making informed choices regarding laser cutter power.

Another prevalent belief is that increased power directly translates to faster cutting speeds. However, this isn’t always accurate. While higher-powered lasers can achieve quicker cuts under certain conditions, the relationship between power and speed is not straightforward. It’s crucial to adjust the cutting speed based on the material type and thickness, as well as the desired finish quality. Sometimes, a lower power setting with an appropriate speed adjustment can yield better results without compromising efficiency.

Many users mistakenly think that high-powered lasers can cut through any thickness of material effortlessly. While powerful lasers are necessary for cutting thicker metals, they are not universally effective across all materials and thicknesses. Each laser cutter has specific limitations regarding the thickness it can handle effectively. For instance, a machine designed for cutting stainless steel may have a maximum thickness it can manage efficiently. Always consult the manufacturer’s guidelines or product manuals to determine the appropriate capabilities of your laser cutter.

Laser cutters are powerful tools that offer precision and efficiency in cutting various materials. However, they also pose significant hazards if not used properly. Understanding the risks and implementing safety measures is crucial for anyone operating these machines.

To mitigate these risks, consider the following safety protocols:

Maintaining laser cutters is vital for ensuring their efficiency and longevity. Regular maintenance not only enhances performance but also minimizes downtime and repair costs. Here’s a detailed guide to keeping your laser cutting equipment in optimal condition.

Why is maintenance crucial for laser cutters? Consistent upkeep helps prevent unexpected breakdowns, ensuring that your operations run smoothly. By adhering to a structured maintenance routine, you can significantly extend the lifespan of your equipment and improve cutting quality.

To effectively manage maintenance tasks, consider implementing a structured schedule:

Laser technology has transformed the manufacturing landscape over the past few decades, continuously evolving to meet modern demands. As industries embrace innovation, laser-cutting machinery is becoming more advanced, enhancing efficiency and precision in various applications. This article highlights the latest trends that are shaping the future of laser cutter power, with a focus on OPMT Laser’s commitment to providing innovative CNC systems and laser processing solutions.

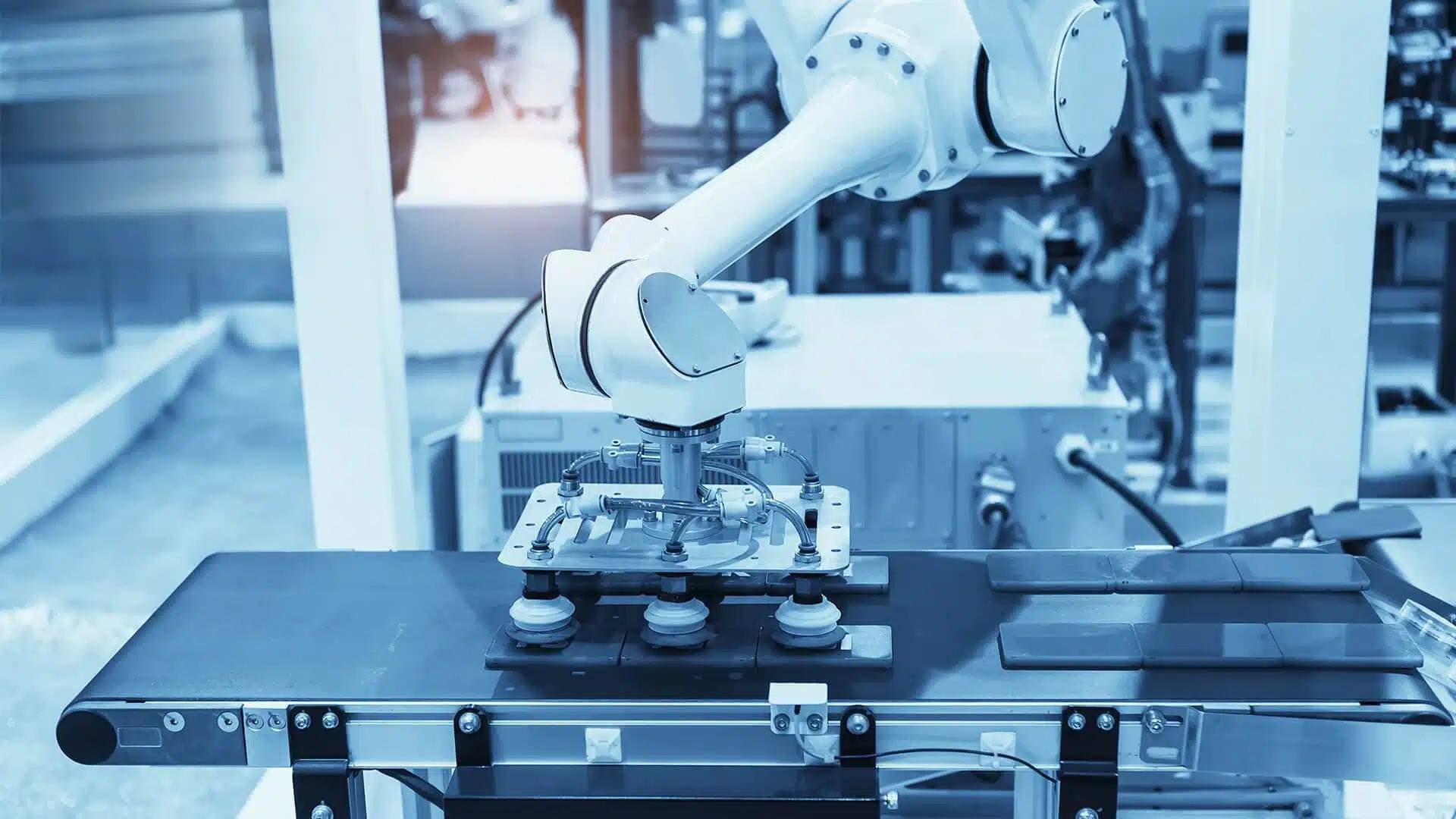

The integration of automation systems in laser cutting is revolutionizing the industry. By incorporating robotics, laser cutters can now execute precise cuts with minimal human intervention. This advancement not only streamlines production but also reduces labor costs. For instance, automated laser-cutting solutions developed by OPMT Laser allow manufacturers to program specific shapes and designs efficiently, enhancing overall productivity.

Modern laser cutters are equipped with advanced control and monitoring features that significantly improve operational efficiency. Real-time monitoring capabilities enable operators to track critical data remotely, ensuring optimal performance at all times. Additionally, cloud connectivity and intelligent material detection facilitate immediate adjustments during the cutting process. These innovations empower manufacturers to maintain high-quality standards while minimizing downtime.

The seamless integration of laser cutters with Computer-Aided Design (CAD) software is another trend gaining traction. This integration allows designers to create intricate designs that can be sent directly to the laser cutter, saving time and increasing accuracy. With tools like OPMT Laser’s cutting-edge systems, manufacturers can streamline their workflow from design to production, ensuring that every detail is executed flawlessly.

Ultrafast lasers are emerging as a game-changer in the industry due to their ability to deliver high precision with minimal heat-affected zones. These lasers are particularly advantageous for applications that require intricate cuts in sensitive materials. By reducing thermal impact, ultrafast lasers ensure cleaner cuts and less material wastage, aligning with sustainability goals in manufacturing.

The development of hybrid laser cutting systems is enhancing flexibility in manufacturing processes. By combining different types of lasers—such as fiber and CO2—these systems optimize performance based on material type and thickness. This adaptability allows manufacturers to tackle a broader range of applications while maximizing efficiency and quality.

As environmental concerns rise, energy efficiency is becoming a priority for laser cutting technology. Modern fiber lasers consume significantly less energy than traditional CO2 lasers while providing superior cutting speeds. This shift not only reduces operational costs but also contributes to global sustainability efforts by minimizing the carbon footprint of manufacturing processes.

Artificial Intelligence (AI) is playing a pivotal role in optimizing laser cutting operations. AI algorithms can analyze material characteristics and adjust cutting parameters in real-time, enhancing productivity while reducing waste. By leveraging AI technology, manufacturers can achieve higher levels of efficiency and precision in their cutting processes.

By staying at the forefront of these emerging trends, OPMT Laser continues to provide innovative solutions that meet the evolving needs of the manufacturing industry. Explore our range of products like the LP550V or Micro3D-L570V to discover how we can elevate your production capabilities today!

Selecting the right laser cutter power for your specific applications is essential for achieving outstanding results. You may be grappling with the complexities of material types, thicknesses, and precision requirements, but understanding these factors can significantly enhance your cutting experience. Did you know that laser cutters can operate anywhere from 10W for delicate materials to over 6000W for heavy-duty tasks?

At OPMT Laser, we promise to guide you through this process, offering a diverse range of laser cutting machines tailored to meet your needs—from CO2 to fiber lasers. Our expertise ensures you make informed choices that align with your project requirements.

Explore our offerings and discover how OPMT Laser can elevate your cutting capabilities today!

Discover OPMT Laser’s ISO 9001-certified femtosecond-pulse CNC systems with sub-300 fs precision, ±0.003 mm tolerance, and AI-driven process control. Learn how top ultrafast-laser partnerships deliver 95% first-pass yields and < 12-month ROI in medical and microfabrication.

Guangdong Original Point Intelligent Technology Co., Ltd. (Original Point Intelligent), established in 2015, is a National Specialized and Innovative “Little Giant” Enterprise and National Intellectual Property Advantage Enterprise. The company

Light 5X 40V-I PCD 5-Axis Laser Machining Solution, premiering at EMO Hannover 2025! Date: 22-26 September 2025Venue: Messegelände, 30521 ,Hannover, Germany | Stand: Hall 4, E08 Following three years of intensive collaborative R&D, OPMT

Comprehensive 2025 guide to selecting the best 5-axis CNC machine. Technical specifications, ROI analysis, and expert recommendations for industrial applications.