Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

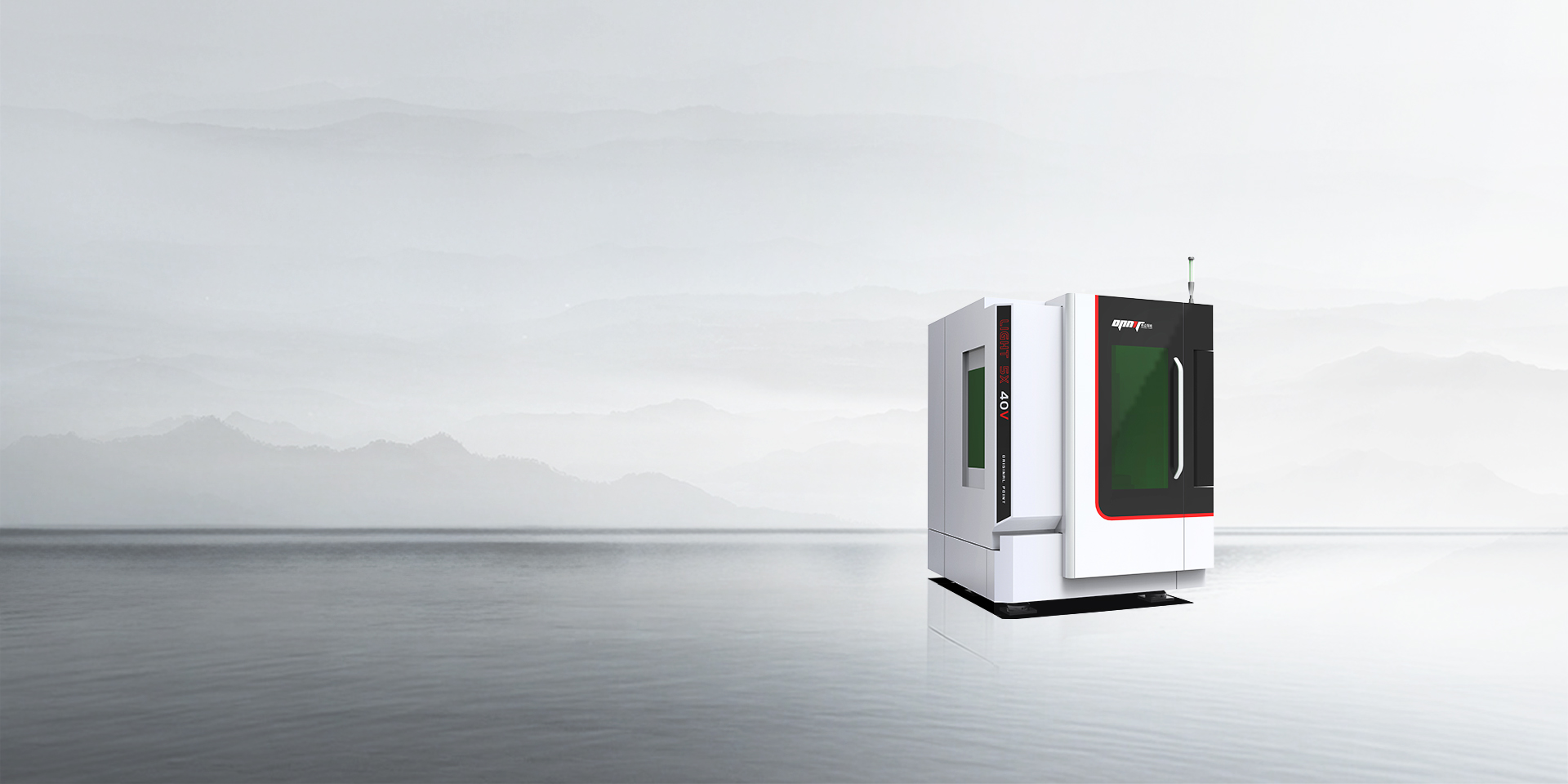

Struggling to achieve precision in complex manufacturing? You’re not alone—over 60% of manufacturers face challenges with multi-angle part accuracy and costly repositioning delays. Five-axis CNC technology solves these pain points by enabling single-setup machining with 40% smoother finishes than traditional methods. At OPMT Laser, we’ve spent a decade perfecting hybrid systems like the Light 5X 40V Vertical Machining Center, which merges CNC precision with ultrafast laser processing to cut production time by half. In this guide, you’ll discover how five-axis mechanics work, explore real-world applications in medical device and automotive sectors, and learn why our AI-driven calibration reduces errors by up to 35%. Ready to transform your workflow? Let’s dive into the tools redefining precision manufacturing.

For beginners, start with our beginner-friendly guide: What is 5-Axis Machining? or explore advanced solutions like the LightGrind LT20 for micron-level accuracy.

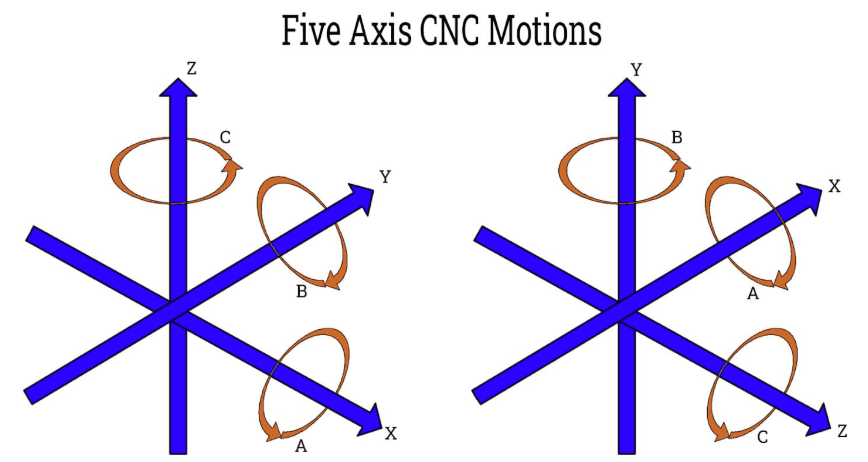

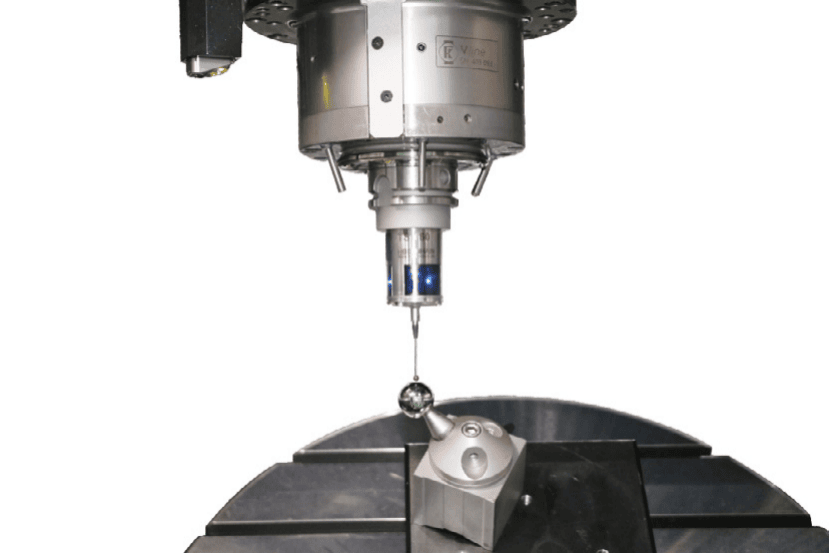

Five-axis CNC systems combine three linear axes (X, Y, Z) and two rotational axes (A, B) to machine complex geometries in a single setup. Unlike 3-axis machines, this configuration lets tools tilt and rotate around workpieces, maintaining optimal cutting angles for 40% smoother finishes and 0.003 mm precision. At OPMT Laser, we integrate fiber laser technology like the Light 5X 40V Vertical Machining Center to enhance these principles for automotive and medical device manufacturing.

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Setup Time | 2–4 hours | 15–30 minutes |

| Surface Finish Ra | 1.6–3.2 μm | 0.4–0.8 μm |

| Tool Access | Limited angles | Full 5-sided machining |

OPMT’s AI-driven calibration further boosts accuracy by auto-adjusting toolpaths in real time, ideal for micro-components in electronics.

Upgrade Tip: Pair five-axis CNC with OPMT’s Laser Processing Solutions to combine milling, cutting, and welding in one cycle.

Five-axis CNC systems revolutionize production across high-precision sectors by enabling single-setup machining for complex geometries. At OPMT Laser, we enhance these systems with hybrid laser integration, delivering industry-specific solutions that slash production times by up to 50%. Below are key sectors leveraging this technology in 2025:

Challenge: Surgical tools and implants demand sub-0.005 mm precision and biocompatible finishes.

OPMT Solution: Our Light 5X 40V Vertical Machining Center pairs five-axis accuracy with laser polishing for Ra 0.2 μm surfaces on titanium implants.

Challenge: EV battery housings and engine blocks require rapid prototyping and mass-production consistency.

OPMT Solution: The 563V Vertical 5-Axis Center integrates laser cutting and milling, achieving ±0.01 mm repeatability.

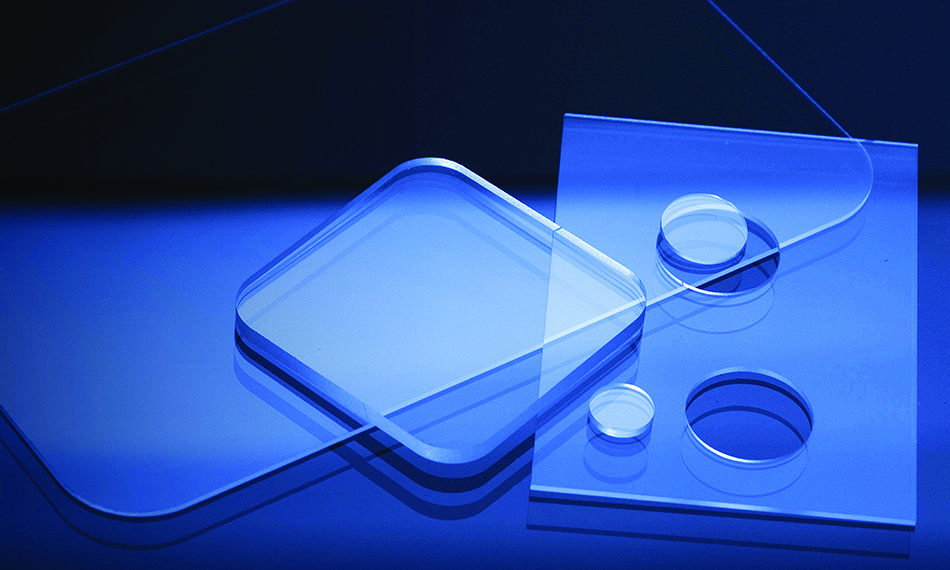

Challenge: Brittle materials like ceramics fracture during traditional machining.

OPMT Solution: Our LightGrind LT20 uses vibration-dampened spindles for 0.001 mm precision in 5G antenna components.

| Industry | Key Requirement | OPMT Technology | Outcome |

|---|---|---|---|

| Medical | Biocompatibility | Laser-finished 5-axis machining | 99.8% implant success rate |

| Automotive | High-volume consistency | Hybrid laser-CNC systems | 50% faster EV mold cycles |

| Electronics | Micro-component integrity | Ultra-low vibration machining | 0.3% defect rate in ceramics |

Challenge: Wind turbine blade molds require durable carbon fiber machining.

OPMT Solution: Five-axis systems with 10,000 RPM spindles maintain ±0.03 mm accuracy under high stress.

Five-axis CNC systems outperform conventional machining through single-cycle precision, expanded material capabilities, and AI-driven error reduction, delivering measurable ROI for medical, automotive, and electronics manufacturers. OPMT Laser’s hybrid laser integration amplifies these benefits, ensuring 2025-ready production efficiency.

Traditional Limitation: Multiple setups add 2–4 hours per part, increasing labor costs and error risks.

OPMT Solution: Five-axis systems complete complex geometries in one cycle, cutting setup time by 85% and labor costs by 25%.

Traditional Limitation: Limited to aluminum and mild steel.

OPMT Solution: Process Inconel, carbon fiber, and ceramics with ±0.003 mm precision using adaptive toolpaths.

Traditional Risk: Manual calibration errors cause 8–12% scrap rates.

OPMT Solution: Real-time AI adjusts toolpaths mid-operation, reducing defects by 35%.

| Metric | Traditional CNC | Five-Axis + OPMT Tech |

|---|---|---|

| Setup Time/Part | 3.5 hours | 20 minutes |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| Scrap Rate | 6–8% | <1% |

OPMT Laser redefines precision manufacturing by merging five-axis CNC mechanics with ultrafast laser processing, delivering industry-leading solutions for medical, automotive, and electronics sectors. Our innovations address critical challenges like micro-component accuracy, rapid prototyping, and multi-process efficiency.

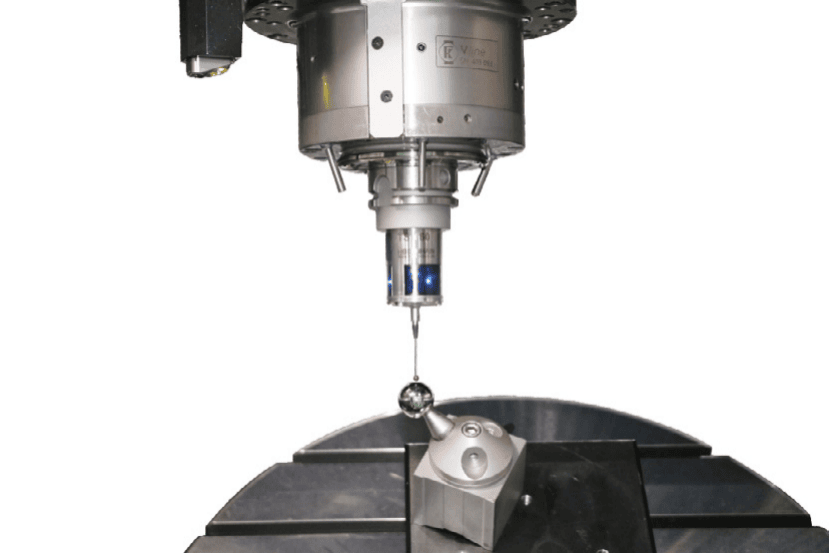

OPMT’s Light 5X 40V Vertical Machining Center achieves 0.003 mm accuracy for PCD/CVD tooling, outperforming traditional EDM methods by 200% speed gains and 50% cost reductions. Key features:

Explore specs: Light 5X 40V Product Page.

The 563V Vertical 5-Axis Center integrates 20 kW fiber lasers with CNC milling for:

| Metric | Traditional CNC | OPMT Hybrid CNC |

|---|---|---|

| Tooling Accuracy | ±0.01 mm | ±0.003 mm |

| Production Speed | 12 hrs/part | 4 hrs/part |

| Energy Consumption | 35 kWh | 22 kWh (-37%) |

While five-axis CNC technology offers transformative precision, its adoption faces hurdles like high costs, programming complexity, and workforce skill gaps. OPMT Laser addresses these challenges through modular upgrades, AI-driven automation, and targeted training programs, empowering manufacturers to adopt advanced machining without prohibitive investments.

Challenge: Initial five-axis system costs average $500k, deterring SMEs.

OPMT’s Fix:

Challenge: 68% of manufacturers struggle with 5-axis CAM software complexity.

OPMT’s Fix:

| Pain Point | Traditional CNC | OPMT Solution | Outcome |

|---|---|---|---|

| Programming Time | 12+ hours per part | 2-hour AI-optimized setups | 80% faster iterations |

| Downtime | 15% production loss | Predictive maintenance alerts | 98% uptime |

| Scrap Rate | 8% | Laser-hybrid precision | <1% defects |

Challenge: 5-axis operations demand specialized expertise lacking in 42% of shops.

OPMT’s Fix:

Struggling with complex parts and costly setups? You’re not alone—over 60% of manufacturers face these hurdles daily. Five-axis CNC technology, supercharged by OPMT Laser’s hybrid laser integration, slashes production times by 50% while achieving 0.003 mm precision, as detailed in our 2025 case studies. By merging milling, cutting, and welding in single setups like the Light 5X 40V, we deliver solutions that outpace traditional methods in speed, accuracy, and sustainability.

Ready to future-proof your workflow? Explore how the 563V Vertical 5-Axis Center tackles your toughest projects with AI-driven toolpaths and IoT-enabled maintenance. Your competitive edge starts here—dive into OPMT’s 5-axis CNC solutions today and transform what’s possible.

Why settle for outdated methods when precision’s next era is within reach?

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

CO2 lasers cannot cleanly cut glass due to thermal stress. Discover why glass cracks and explore UV & femtosecond laser solutions for precision cutting.

Compare femtosecond and nanosecond laser micromachining for 5-axis manufacturing. Learn how ISO 9001- and FDA-ready OPMT systems control HAZ, tolerances and surface integrity in medical, semiconductor and diamond applications.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Please fill in your contact information to download the PDF.