Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

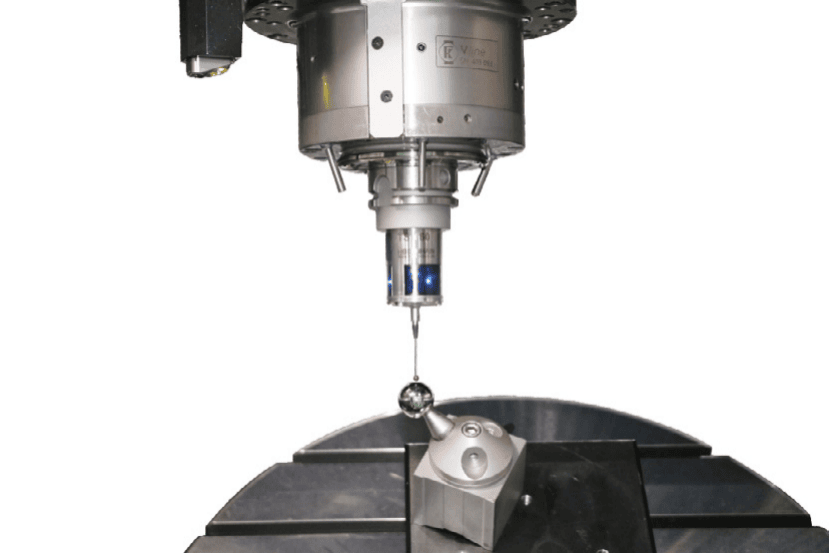

In a high-tech aerospace workshop, a five-axis CNC machine sculpts nickel-alloy turbine blades with ±0.005mm precision. These components, featuring over 200 freeform surfaces, traditionally required 20 manual setups. Today, CNC systems complete them in 72 hours—a testament to how these “industrial mother machines” drive modern manufacturing.

China’s CNC machine market surpassed ¥260 billion ($36 billion) in 2024, yet domestic manufacturers hold less than 10% of the high-end segment. Bridging this gap is OPMT Laser, a pioneer in multi-axis CNC and laser processing solutions. With 250+ patents and collaborations with Tsinghua University, OPMT’s Micro3D-L530V Five-Axis Laser Center slashes titanium part costs by 40% while achieving 99.7% yield in semiconductor wafer cutting.

This article explores CNC machine classifications, industry-specific applications, and innovations reshaping precision manufacturing.

CNC machines are categorized by their primary operations, but modern systems increasingly combine multiple processes.

Key Types:

Trend: Automotive suppliers now use turn-mill centers to reduce setups by 70%, cutting camshaft production cycles from 8 hours to 2.5 hours.

Motion control defines a machine’s capability and price tier:

| Control Type | Accuracy | Applications |

|---|---|---|

| Point-to-Point | ±0.1mm | Drilling, stamping |

| Contouring | ±0.005mm | Aerospace blades, 5G molds |

OPMT’s SmartDrive Servo System uses real-time feedback to achieve ±0.001mm positioning, outperforming traditional ball-screw systems by 50% in accuracy.

Servo systems determine speed, precision, and energy efficiency:

Breakthrough: OPMT’s LightGrind-LT20 Laser Grinder replaces diamond abrasives, reducing coolant use by 90% while grinding tungsten carbide tools to Ra 0.05μm.

Machine learning optimizes parameters in real time:

Case Study: A medical supplier cut implant costs by 18% using OPMT’s AI-optimized toolpaths.

Green technologies minimize waste and energy use:

Impact: Adoption in automotive plants has lowered CO2 emissions by 30% per part.

IoT-enabled systems enable flexibility and predictive maintenance:

OPMT’s Light-5X-60V Platform supports 10+ material types, from lab-grown diamonds to Inconel 718.

CNC machines produce mission-critical components like titanium turbine blades and CFRP wing ribs for next-gen aircraft.

Key Challenges:

Case Study:

A leading jet engine manufacturer reduced blade scrap rates from 8% to 0.9% using OPMT’s adaptive thermal compensation, saving $4.2M annually.

EV production demands CNC systems for aluminum battery housings, carbon fiber chassis, and high-precision motor components.

Innovations:

Data Impact:

| Metric | Traditional CNC | OPMT Laser CNC |

|---|---|---|

| Cycle Time | 8 hours | 2.5 hours |

| Material Waste | 12% | 2.5% |

CNC machines craft titanium spinal implants and surgical tools with biocompatible surfaces.

Critical Requirements:

Breakthrough:

A Swiss medtech firm reduced implant rejection rates by 22% using OPMT’s non-contact laser polishing.

Machine learning algorithms now predict tool wear with 95% accuracy, optimizing maintenance schedules.

OPMT’s Edge:

Sustainability drives innovation in CNC technology:

Regulatory Push:

EU’s Carbon Border Tax incentivizes adoption of eco-friendly CNC systems like OPMT’s ISO 14955-compliant machines.

OPMT’s L100V Benchtop CNC brings 5-axis capabilities to SMEs at 1/3 the cost of industrial systems.

Key Features:

While China’s CNC industry still imports 85% of high-end controllers, firms like OPMT Laser prove domestic innovation can disrupt global markets. With ¥34M in provincial R&D grants and partnerships with Tsinghua University, OPMT’s 5-axis laser systems now rival German and Japanese counterparts at 60% lower cost.

Three Strategic Priorities:

The next decade will see CNC technology converge with quantum computing and advanced materials science—a revolution where precision meets possibility.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

CO2 lasers cannot cleanly cut glass due to thermal stress. Discover why glass cracks and explore UV & femtosecond laser solutions for precision cutting.

Compare femtosecond and nanosecond laser micromachining for 5-axis manufacturing. Learn how ISO 9001- and FDA-ready OPMT systems control HAZ, tolerances and surface integrity in medical, semiconductor and diamond applications.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Please fill in your contact information to download the PDF.